Step utilization ofsteel slag

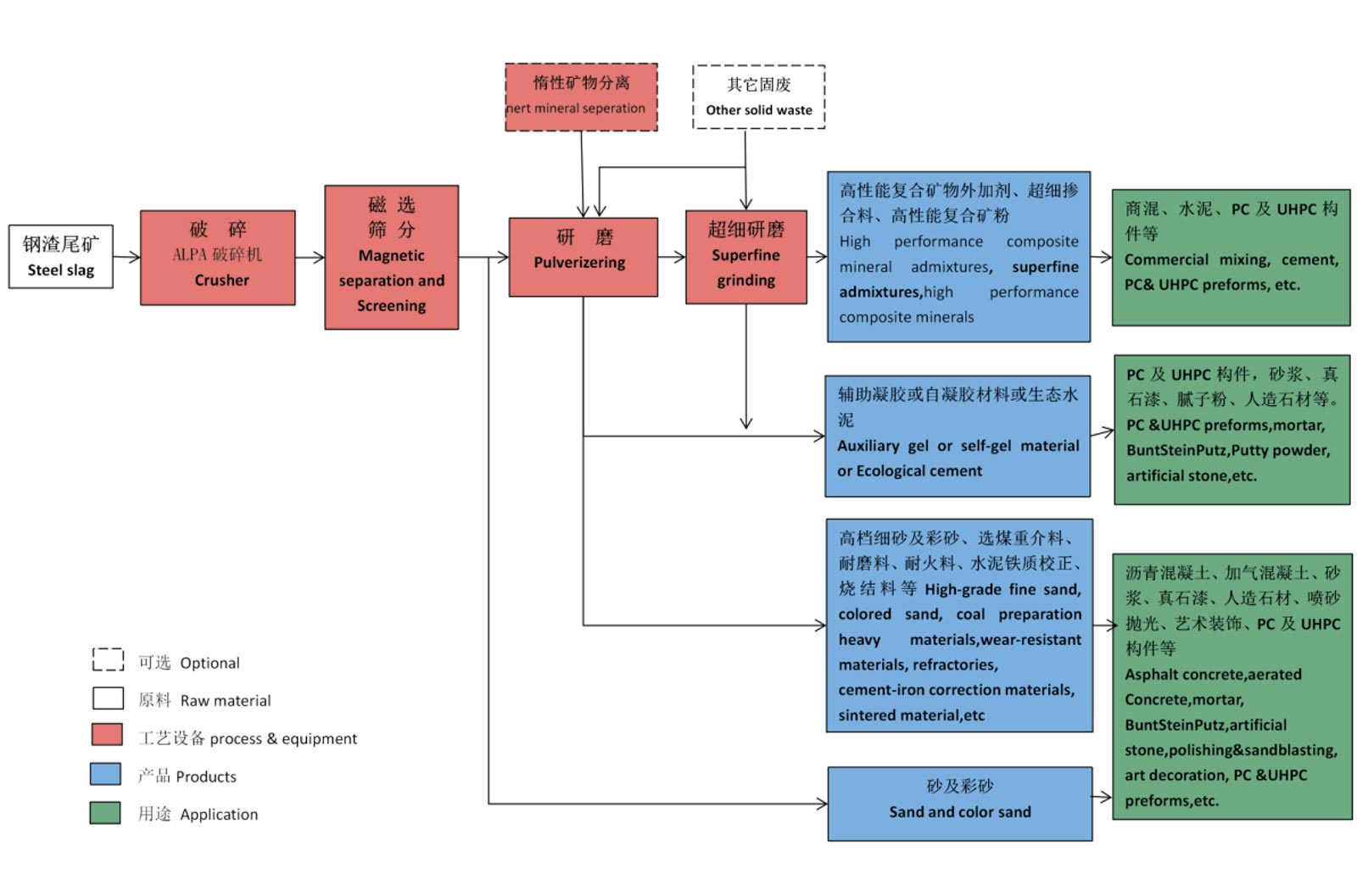

Demonstration and introduction of the industrialization of cascade utilization of steel slag based on green low-cost processing and multi-solid waste synergistic cementing tree

01

Crushing iron separation

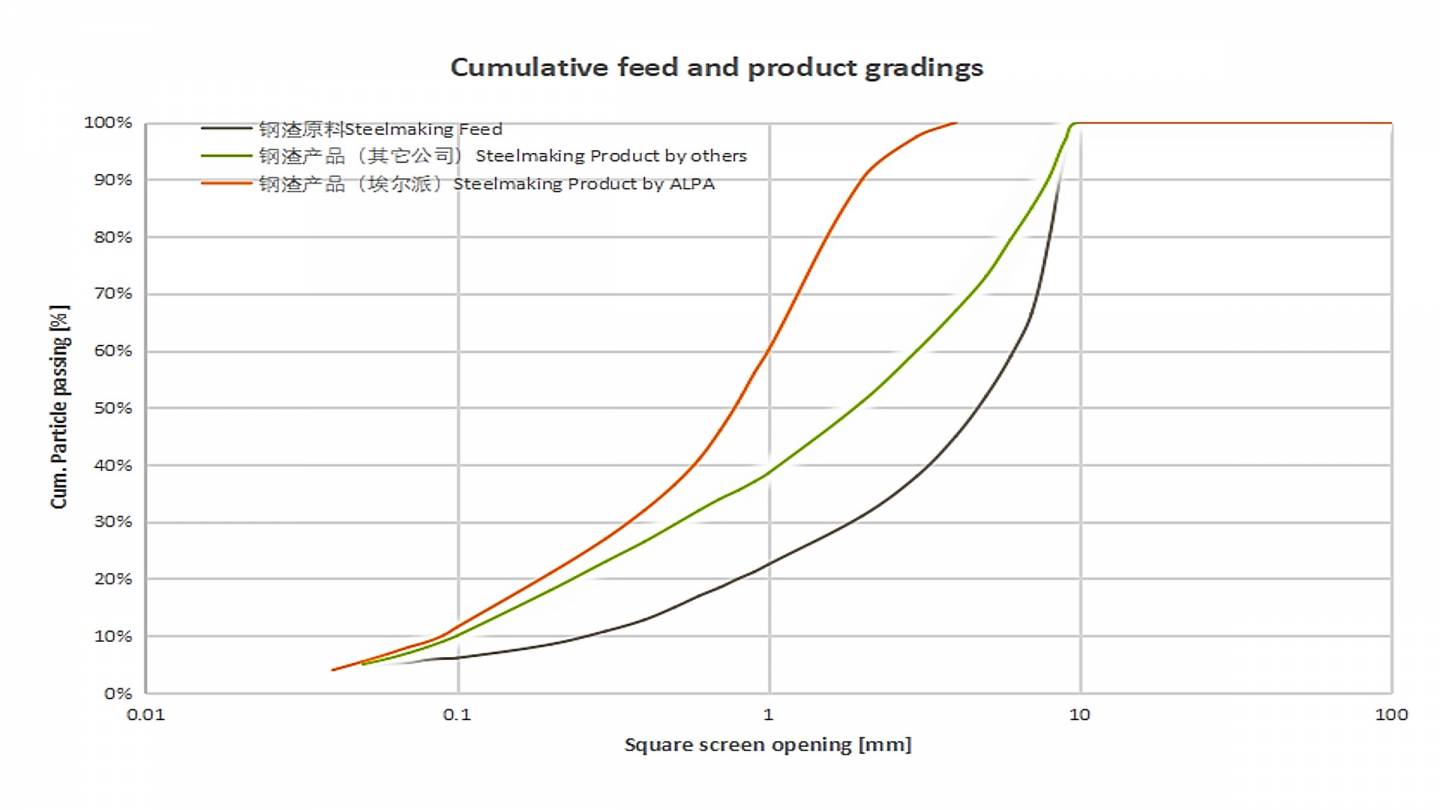

- Steel after crushing choose iron steel tailings or after stuffy slag crushing primary piece of steel, the steel slag, using German technology manufacturing el pie tiger impact crusher, 50 mm to fine into the largest expected, one-time crushing with fine accounted for about 50%, to 1 mm 2 mm with fine accounted for more than 90%, 100% less than 5 mm. The fineness can be adjusted, the output of the platform can be selected from 70-400 tons, and the energy consumption per ton is only about 2 degrees of electricity.

- The tiger crusher selective crushing degree is high, material is fine. After the material is broken, the metal iron is first selected by weak magnetic separation, with the selection grade up to 85% and the selection rate up to 80%.The iron content of tailings can be reduced to 0.5%.

- By magnetic separation can also put some iron oxide and elected RO phase. After magnetic separation, the inert matter of the fine slag powder is reduced, and its activity and wearability are improved, which provides favorable conditions for subsequent processing and application.

02

Making sand and colored sand

After magnetic separation, the slag powder can be directly screened to produce sand, which can be used for road asphalt concrete, plastering mortar, masonry mortar, bonding mortar, as well as building blocks, bricks, wall materials and other building materials.

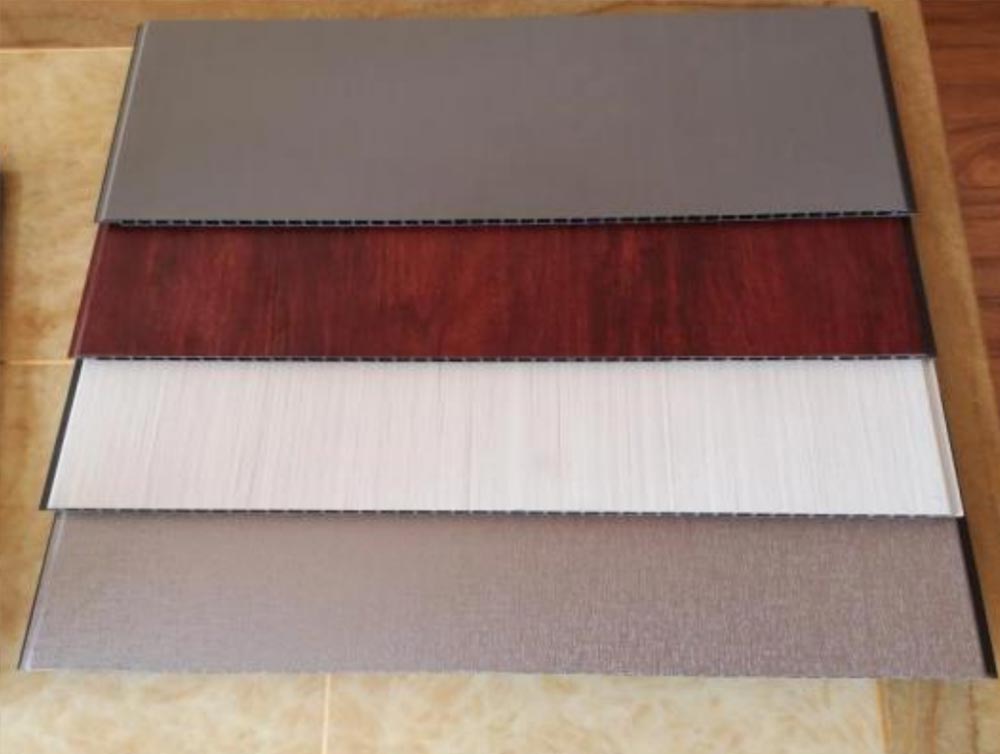

Colored sand can be made by formula coloring and curing after sand making. Colored sand is widely used in architecture and art. The application in the field of architecture is mainly used in roof (such as bitumen colored tiles), wall (real stone paint, etc.), ground (such as colored floor, colored pavement, etc.), home decoration (such as imitation marble countertops, colored household profiles, etc.);In the arts and crafts, such as colored sand painting, colorful handicrafts.

With the progress of science and technology and the improvement of living standards, the application of colored sand will be more extensive.

03

The preparation of self - cementing or auxiliary cementing materials and their products

as well as high performance compound mineral additives are introduced

Self-cementing or auxiliary cementing materials and high performance composite mineral additives are produced by using the tailings after the above-mentioned screening and sand preparation, or by using the micro slag powder after magnetic separation directly, and by using the advanced low-cost processing and multi-solid waste cooperative excitation technology. The utilization of building materials is the main way of large-scale utilization of solid waste. The key technique is deep activation. Ultrafine pulverization is an important way to stimulate the activity of industrial solid waste.

Steam grinding and ultrafine ball grinding are advanced and low-cost technologies to realize ultrafine pulverization of solid waste. Combined with the principle of multi-solid waste cooperative excitation, self-cementing or auxiliary cementing materials and high-performance composite mineral additives can be prepared.

The above since the gel or auxiliary cementitious materials can replace or save M series masonry cement, PC series composite Portland cement and so on, are widely used in industrial and civil architecture really stone paint (instead of some organic emulsion), putty powder, masonry and plastering mortar, bedding and backfill concrete, wall materials and fabricated parts, brick block, inorganic stone slab (instead of natural stone, artificial stone, brick of pottery and porcelain, etc.), stone series, all kinds of PC components, etc. In particular, it can be prepared into a variety of prefabricated building materials and sponge city water permeable materials, ultra-thin and high strength inorganic stone plates (instead of natural stone and ceramic plates), UHPC ultra-high performance concrete components.

Relevant interpretation

Industry market background | Experimental brick machine made in our own plant | Innovative technology and equipment — pressure controlled foaming machine | Combination design of pervious material and water storage material | Solid waste composite cementite putty powder | Stone plastic series products industrial background and innovative technology equipment |

04

Inert mineral separation

RO phase is the main inert mineral in steel slag. According to the lithofacies characteristics of steel slag and the occurrence morphology, crystal structure, particle size, density, hardness, magnetism and electrical properties of RO phase, grinding and weighting separation, magnetic separation and other methods can be used to effectively separate the inert and active substances in steel slag economically.

After separation, the content of RO phase in the active substance can be reduced to less than 10%, and the activity can be increased by 20% compared with the original slag powder with the same fineness.

05

Solving key common problems

The key common problems affecting the comprehensive utilization of steel tailings and their solutions are mainly in the following three aspects:

- Poor wearability: selective and efficient crushing and iron selection; Dynamic magnetic separation or inert matter separation during grinding;

- Poor activity: separation of inert matter; Increased fineness; Multiple solid waste synergistic excitation;

- Poor stability: after increasing fineness, free calcium oxide and free magnesium oxide uniformly disperse and synchronously hydrate in the hydration system and participate in the gelation reaction, and the resulting micro-expansion effect makes up for the shrinkage of the system.

06

Key innovation technology and process equipment

Selective and efficient crushing and iron separation; Superfine pulverization of supersonic steam; Classification of ultrafine ball mill; High efficiency separation of inert matter; Multi-solid waste compound with synergistic gelation; Inorganic gel wrapping; Mechanical hole-making – static forming; Pressure controlled foaming.

Examples of engineering applications

Introduction of 2.8 million ton steel slag cascade utilization project

The project is divided into five sub-projects, with an annual total utilization of about 2.8 million tons of steel slag, an annual sales revenue of about 2.33 billion yuan, an annual profit and tax of about 890 million yuan, and a total investment of about 495 million yuan.

Annual output of 10 million square meters of solid waste based artificial stone project

Using solid waste to prepare artificial stone products has the…

Annual output of 30 million square meters of solid waste based composite plate project

After the project is put into operation, it will produce 30 million square…

Annual output 300,000 tons of solid waste artificial colored sand project

After the project is put into operation, it will produce 300,000 tons of…

Annual output of 500,000 tons of solid waste construction plaster project

After the project is put into operation, 500,000 tons of solid waste…

Annual production of 1 million tons of superfine steel slag powder project

Because steel slag has problems such as poor stability, low activity, and…

Contact Us

You can email us

24-Hour Consultation Hotline

Head office Address

No. 168 Wenhua Road, Anqiu, Weifang City, Shandong Province, China

Please tell us what you need

Our engineers will contact you within 12 hours and provide free proposal and quotation.