Annual output of 30 million square meters of solid waste based composite plate project

一、Project background

Using solid waste to prepare composite board products has the characteristics of large solid waste consumption and high added value. The main solid wastes include steel slag powder, fly ash, coal gangue powder and other bulk industrial solid wastes. The product is organic-inorganic composite board. The product can be widely used in building interior decoration (including floor, wallboard and roof), industrial building supporting board, container lining board, etc. its added value can be as high as 3000 yuan / T solid waste, showing good economic and social environmental benefits.

二、Project design scheme

2.1 Production scale

Annual production of steel slag based (or other solid waste based) composite plate 30 million square meters. Annual production time: 6000 hours.

2.2 Material

Raw materials for the project include 400000 tons of steel slag powder and 100000 tons of polymer plastics. Total raw materials: 500000 tons.

2.3 Products

Steel slag powder composite plate: 30 million square meters / year.

The products are mainly used for interior decoration (including floor, wallboard and roof), industrial building supporting board, container lining board, etc.

2.4 Technical scheme of production process

2.4.1 Production technology and process flow

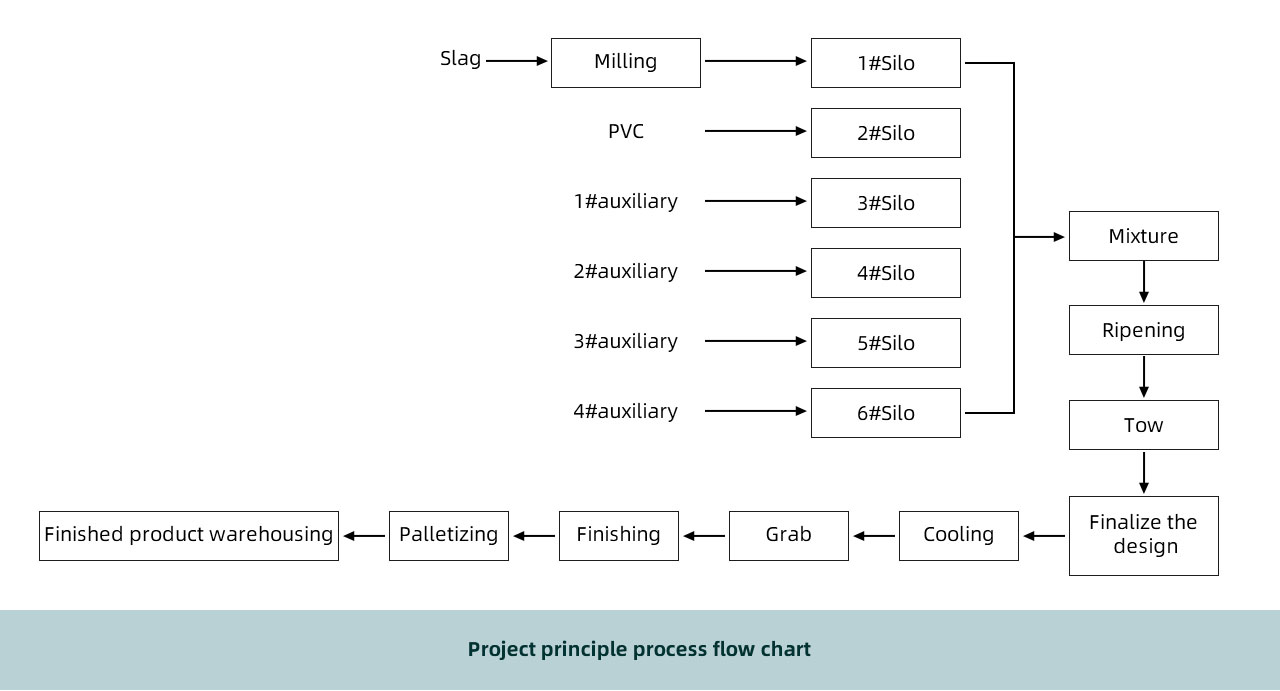

The overall process technology of the project is described as follows: with steel slag powder and organic polymer as raw materials, the qualified products are produced through “raw material pretreatment – quantitative feeding – raw material homogenization – hot melt plasticization – extrusion molding – cooling setting – cutting – finishing” and other processing procedures.

2.4.2 Main equipment system

The process equipment system of this project mainly includes:

(1) Raw material buffer system;

(2) Raw material pre-processing system;

(3) Raw material quantitative feeding system;

(4) Raw material homogenization system;

(5) Hot melt plasticizing system;

(6) Extrusion molding and cooling setting system;

(7) Cutting and slotting system;

(8) Finishing system;

(9) Central control system.

The overall process flow diagram of the project is shown in the figure below.

2.5 Land occupation of the project

The project covers an area of 20000 m2 (about 30 mu).

2.6 Plant conditions

1) Power consumption: the total installed capacity of the project is about 11000kW, and the annual power consumption is 75 million kwh.

2) Water consumption: the circulating water for production is about 450 t / h, and the water consumption is 25000 T per year.

3) Transportation: the transportation of raw materials and finished products can be met by using the existing roads of the manufacturer, and the total annual transportation amount is 1 million tons.

三、Environmental protection

Electricity is used as the energy medium in the production of this project, and there is no sewage, smoke, solid waste and other pollutants in the production process.

四、Project schedule

The construction period of the project is 10-15 months, including 6-8 months for engineering design and equipment procurement, 3-5 months for on-site construction, installation and commissioning, and 1-2 months for trial production, commissioning and normal production.

五、Staff plan

A total of 200 people. Among them, there are 10 quality inspectors, 70 loading workers, 100 random inspectors and 20 other auxiliary personnel.

六、Investment estimation

The investment in fixed assets of the project is expected to be 200 million yuan, including 120 million yuan for equipment, 50 million yuan for civil engineering and installation, and about 30 million yuan for other investments.

七、Benefit analysis

7.1 Annual sales revenue: 1.2 billion yuan / year.

After the project is put into operation, the normal annual output is 30 million square meters of composite plate, and the product sales price is 40 yuan / square meter (market price is 40-120 yuan / square meter), so the annual operating income is about 1.2 billion yuan.

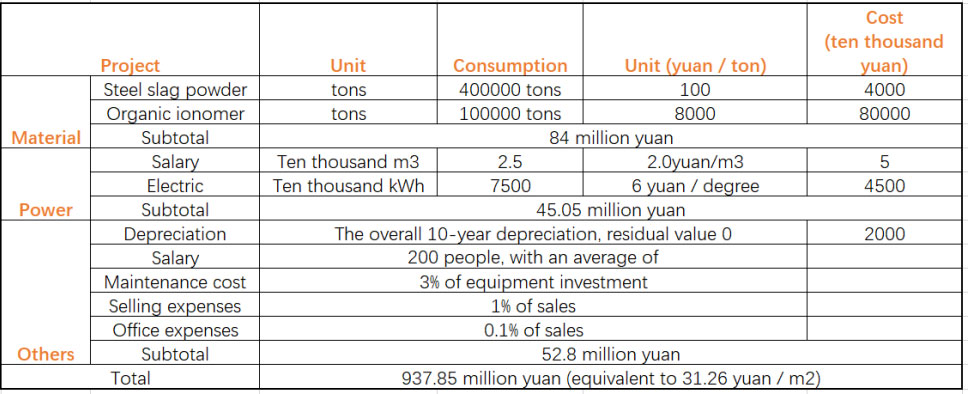

7.2 Annual total cost: 937.85 million yuan.

The annual total cost mainly includes power consumption, labor, sales, management, depreciation, maintenance, etc., totaling 937.85 million yuan. The cost structure is shown in the table below.

7.3 Year profit and tax analysis

After the completion of the project, the annual sales revenue is 120 million yuan, the annual operating cost is 937.85 million yuan, and the annual profits and taxes are 262.15 million yuan. The payback period of investment is about 2 years (including 1 year construction period).

八、Conclusion

After the project is put into operation, it will produce 30 million square meters of solid waste based composite board annually. The products can adapt to different market demands, such as decorative board, building supporting board, industrial lining board, etc. by changing the forming mold. The products have a wide range of uses, huge market capacity and smooth sales channels.

The investment of the project is 200 million yuan, the annual solid waste treatment is 400000 tons, the annual output value is 120 million yuan, the new annual profit and tax is 262.15 million yuan, which has significant economic and social environmental benefits, and the project is feasible.