Overview of Modification Process

Surface modification with important practical significance to improve the properties of the powders, increase the practical value and develop the application fields.

In plastics, rubber, adhesives and other polymer materials and composite materials, nonmetal powder fillers, such as calcium carbonate, kaolin, talc, quartz, wollastonite, asbestos, magnesium hydroxide, aluminum hydroxide, etc., must be modified on surface to enhance its compatibility with matrix, dispersion, mechanical strength and comprehensive properties.

Surface modification is one of the necessary processing methods for filling materials from general incremental fillers to functional fillers, and it is also the main purpose of surface modification of mineral fillers. The main functions of surface modification of mineral fillers include dispersion, viscosity reduction, filling and interfacial mechanics. The most commonly used modification methods are surface chemical modification, coating modification and mechanochemical modification. The research contents include modification mechanism, modifier, modification process and equipment, process control, product testing and evaluation, etc.

Basic Process Conditions

The purpose, method and agent of modification are different, and the process and equipment is also different. But the basic principle of modification is to obtain the highest coating rate or modification effect with the least coating material or cost.

The surface modification process should meet the application requirements or application conditions of the modifier, the modifier has good dispersion, can realize the uniform and firm coating of the modifier on the powder surface, the process parameters are controllable, and the product quality is stable.

- The modifier uses dilution, emulsification, spray addition and other measures to improve dispersity, preferably continuous spray or drop with continuous powder feeding.

- The precise measurement of modifier and material and the uniform addition and feeding ensure the instantaneous accuracy of their mixing ratio;

- The control of system temperature and time should meet the requirements of modification mechanism or modifier on process conditions to ensure the sufficiency of modification reaction or coating;

- The equipment has good operating conditions;

- Other factors, such as the use of auxiliary equipment, such as the use of a disintegrator or classifier,environmental factors (temperature, humidity), etc.

The key to the performance of surface modification equipment lies in its operation characteristics

It can make the material and the modifier fully and evenly contact and have a good dispersion state, so as to achieve uniform single molecule adsorption and reduce the amount of modifier.

The temperature and time of the reaction can be adjusted, so that the reaction can be carried out at the best temperature and time to achieve good surface chemical modification effect.

Low energy consumption and wear, good operating environment.

01 Turbo Mill surface modification process

Principle and characteristics: use conical rotor and stator, the gap between the rotor and stator can be adjusted; the linear speed of the rotor can reach 120 m / S; the high-speed impact, shear and friction of materials between the rotor and stator complete the coating process.

Power range: 22kW-110kW

Maximum capacity: 4t/h

Advantages:

- Large air volume, using vortex generated by high-speed rotation of equipment, fully dispersed, high coating rate, no dead zone;

- Adjustable pulverizing device is suitable for coating modification of 325 ~ 3000 mesh powder with wide particle size range;

- External heating device, controllable temperature and stable product;

- Accurate measurement of spray device, automation, less dosage of modifier;

- The coating time can be controlled by the external induced draft fan to adapt to the coating of different modifiers.

Technical parameter

Model | RTM-300 | RTM-400 | RTM-500 | RTM-750 | RTM-1000 |

Particle size | D97:10μm | D97:10μm | D97:10μm | D97:10μm | D97:10μm |

Size | 500kg/h | 900kg/h | 1500kg/h | 2000-2500kg/h | 4000kg/h |

Power | 22kW | 37kW | 45kW | 75kW | 110kW |

02 Modification technology of Honeycomb Mill

Principle and characteristics: when the equipment is running at high speed, it drives the strong air flow, so that the agglomerated powder particles stay in the stator of the equipment, and the stator is designed as a special groove. The strong vortices formed by wind pressure and wind speed will produce shear force, friction force and centrifugal force, which can quickly break the materials into single particles and reduce them to the original particle size or natural crystal particles.

Maximum capacity: 4.5t/h

Advantages:

- It integrates drying and crushing functions, with high efficiency and low operation cost;

- It can withstand high temperature of 400 ℃, and the bearing adopts heat insulation design;

- The grinding block and grinding lining can be replaced, and the grinding block of different materials can be selected according to different materials;

- The internal grading wheel can be selected to grind coarse materials circularly in the mill;

- It can be connected with external heating air and realize drying and dispersing functions at the same time. Under the action of high-speed rotor, materials and hot air can be fully contacted in the crushing and dispersing area. The heat exchange area is large, and the water can be taken away effectively. The heat source can be used more efficiently, saving energy by 30% – 50% compared with traditional drying.

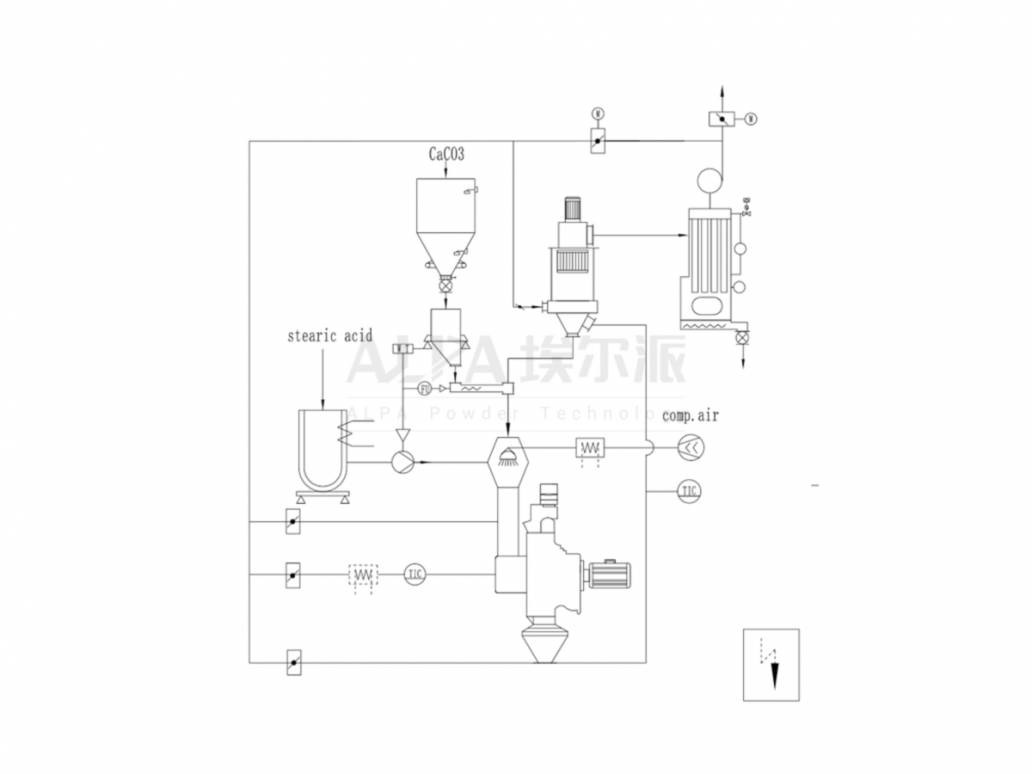

03 Three-roller Mill surface modification process

Principle and characteristics: the relative motion of three rotors can change the effect of cyclone and eddy current to realize the coating of powder surface. Without heating device, it has the advantages of low investment and low operation cost.

Power range: 11kW ~ 225kW

Maximum capacity: 6t/h

Advantages:

- The process is mature and investment is low, which is suitable for coating modification of stearic acid. Self-friction heat generation, less accessory equipment;

- It is suitable for the modification of 325 ~ 1250 mesh powder.

Disadvantages:

- Low air volume, dispersion was weak, especially fine powder, with more modifier dosage;

- Self-friction heat generation is easy to be affected by environmental factors, and hard to control the modification temperature ;

- There is dead zone and low coating rate.

Technical parameter

Model | SG200 | SG3/300 | SG3/600 | SG3/900 |

D97:10μm | 150kg/h | 1.5t/h | 3t/h | 6t/h |

Power | 11kW | 55.5kW | 111kW | 225kW |

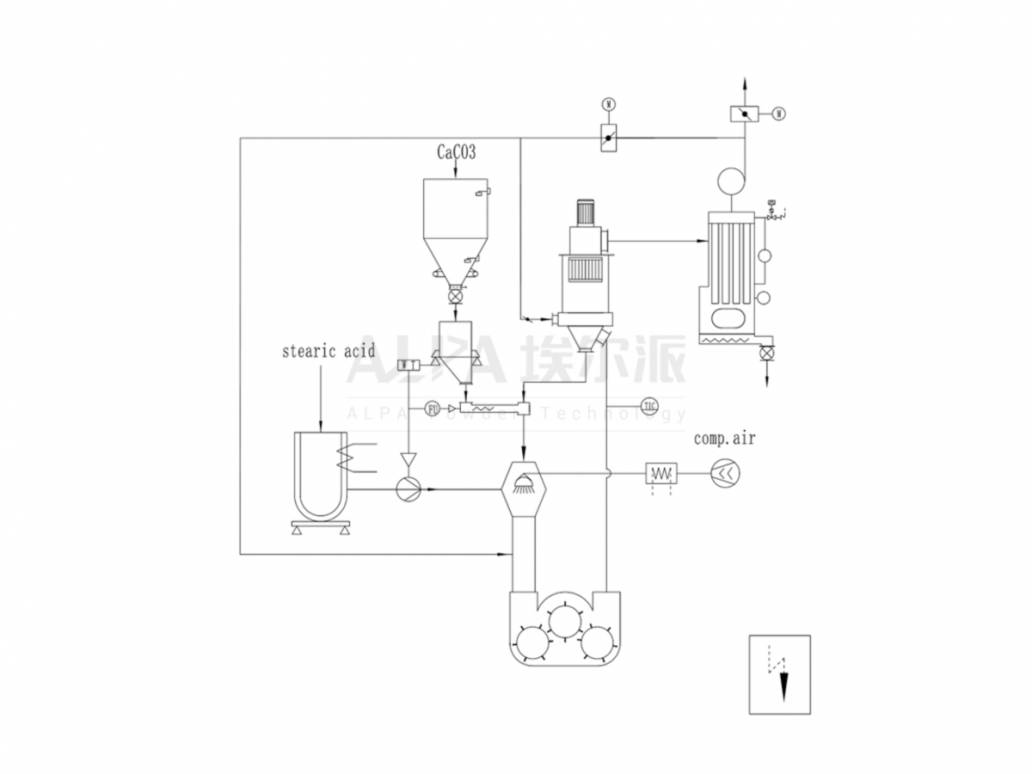

04 Modification process of Pin Mill

Principle and characteristics: the two rotors are in relative motion, and the linear velocity is as high as 200m / s. High speed impact, shear and friction lead to the full dispersion of materials and the sharp rise of temperature to meet the needs of particle coating.

Particle size range: D97: 5μm~15μm

Maximum capacity: 7.2t/h

Advantages:

- It has a wide range of applications and can achieve ideal activation effect for various inorganic mineral powders;

- The precise measurement and uniform addition of modifier and material can ensure the instantaneous accuracy of the ratio of modifier and material, realize the uniform and firm coating of modifier on the powder surface, good controllability of process parameters and stable product quality;

- The modified powder has the functions of dispersing, reducing viscosity, increasing filling and interface mechanics;

- The surface of polymer materials and composite materials such as plastics, rubber and adhesives are modified to enhance their compatibility with matrix, dispersion, mechanical strength and comprehensive performance;

- The whole system is easy to operate, with high degree of automation, high efficiency and low cost.

Technical parameter

Size/Capacity/Model | CUM-P200 | CUM-P400 | CUM-P630 | CUM-P800 |

D97:5μm | 300kg/h | 700kg/h | 1800kg/h | 3000kg/h |

D97:10μm | 500kg/h | 1300kg/h | 3300kg/h | 5800kg/h |

D97:15μm | 600kg/h | 1600kg/h | 4000kg/h | 7200kg/h |

05 Modification process of High-speed Mixer

Principle and characteristics: batch work. It is suitable for silane and other additives to modify materials with high temperature and long reaction time, with heating and timing devices, and the modification temperature and time can be controlled. The lining can be made of ceramic material with zero metal pollution.

Advantages:

- With heating and timing device, modification temperature and time can be controlled;

- It has a wide range of application, and can achieve ideal activation effect for various inorganic mineral powders;

- Through the coordination of uniform feeding and quantitative feeding of modifier, the sufficiency of material coating is ensured;

- The control of system temperature and time ensures the sufficiency of modification reaction or coating.

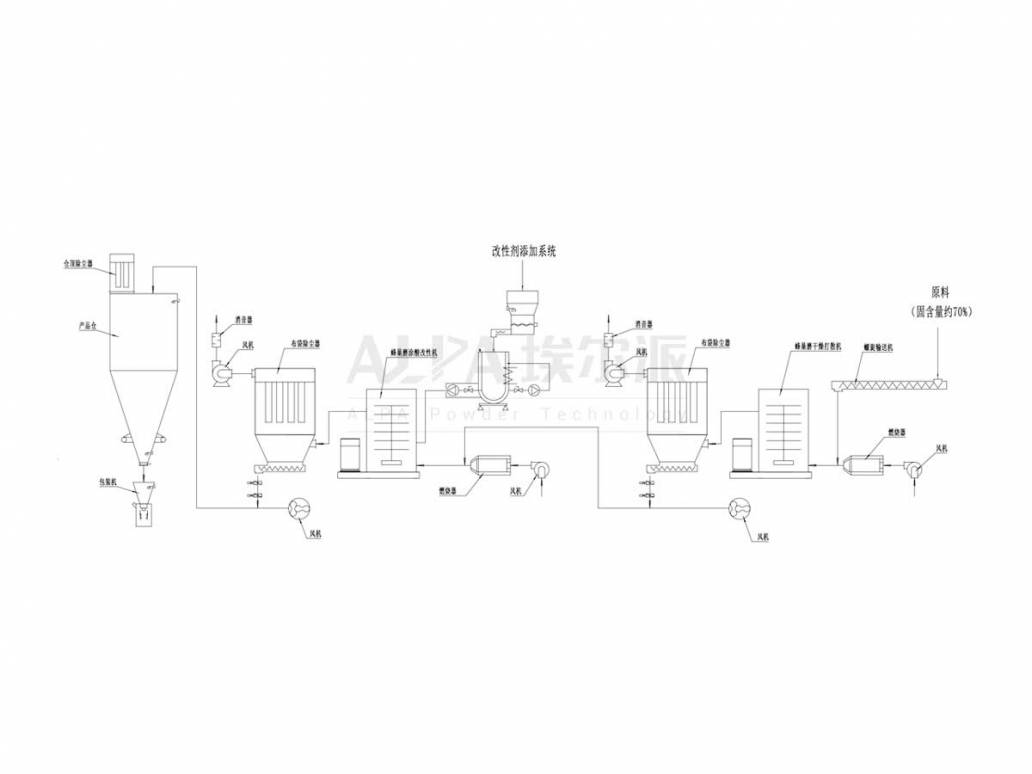

Continuous modified production process

The continuous production process is usually after the dry powder preparation process to produce a large number of non-metallic mineral active powder, especially for plastics, rubber, adhesives and other polymer based composite materials of inorganic fillers and pigments.

Continuous surface modification process refers to the process of continuous feeding and continuous adding surface modifier. Therefore, in the continuous powder surface modification process, in addition to modifying the main equipment, there are continuous feeding device and dosing (adding surface modifier) device. Because the production equipment used in the continuous modification process is different from the intermittent modification equipment, the continuous modification production can be carried out in large quantities to meet the production needs of large enterprises.

Batch modified production process

The modification time and temperature can be adjusted by batch modification, it has strong adaptability to different modifiers and (compound) formulations, suitable for surface chemical modification of small and medium-sized powders, such as coupling agent, especially silane coupling agent. The operating conditions include rotating speed, temperature, time, filling rate, adding method of modifier, etc.

Batch modification process is to feed the metered powder raw materials and a certain amount of prepared surface modifier into the surface modification equipment at the same time, carry out surface modification treatment for a certain time at a certain temperature, and then unload the processed materials, and then add materials to carry out the surface modification of the next batch of powders. It is usually used with air classifier to separate agglomerated particles in the modification process and improve the product quality.

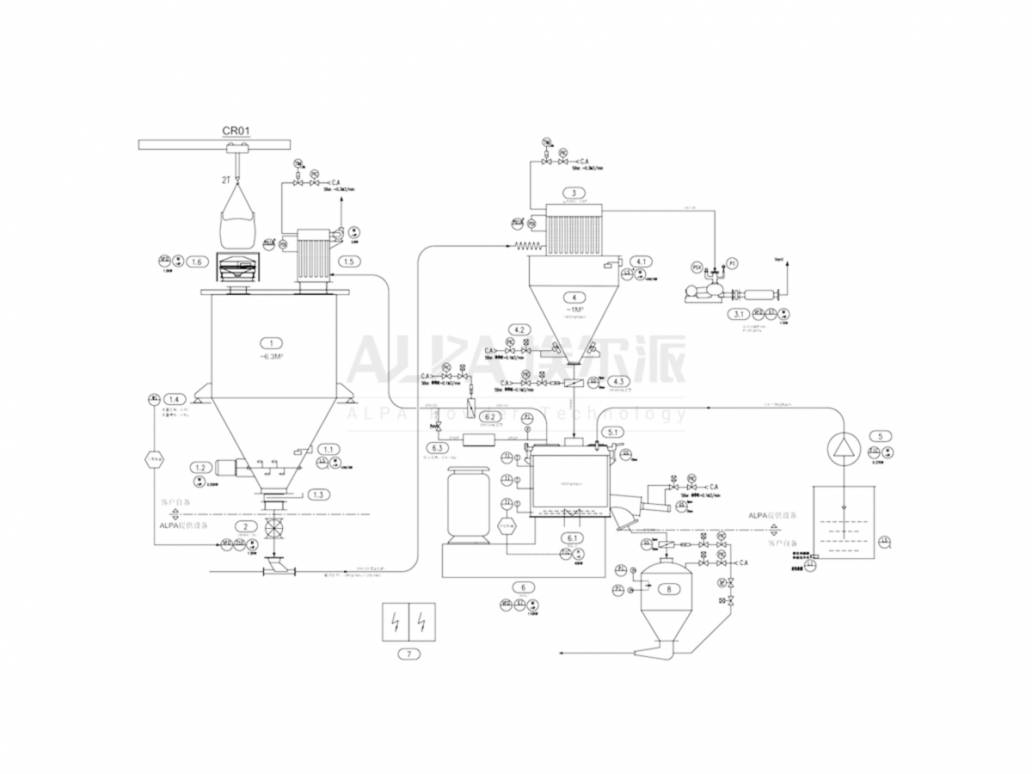

Compound modified production process

Composite modification production process is a process of Integrated Modification of various equipment. It is a process that surface modifier is added in the process of mechanical force or fine grinding and ultra-fine grinding, and the particle size is reduced while the surface chemical coating modification is carried out. This process combines the characteristics of continuous modification production process and intermittent modification process, and has the characteristics of uniform and firm modifier coating, good controllability and stable product quality. It is often used with depolymerizer or classifier.

Contact Us

You can email us

24-Hour Consultation Hotline

Head office Address

No. 168 Wenhua Road, Anqiu, Weifang City, Shandong Province, China

Please tell us what you need

Our engineers will contact you within 12 hours and provide free proposal and quotation.