ALPA’s core technology

- High efficiency selective crushing

- Low cost superfine grinding and superfine classification

- Multi solid waste compounding and collaborative cementation

- Functional modification

- Inorganic gelation package

- Mechanical drilling static pressure forming

- Pressure controlled foaming

The research direction of ALPA

- Step utilization of steel slag - from superfine admixture to auxiliary cementitious materials and products

- The step utilization of fly ash from admixture to inorganic filler

- High value utilization of coal gangue, tailings, red mud, etc-- Stone plastic series and inorganic stone, etc.

- High temperature slag sensible heat recovery and tail slag ultrafine powder preparation

- Enrichment and separation of valuable components from metallurgical slag, tailings and lean ore

- Fine preparation of various bulk solid waste powders and products

ALPA's new technology of industrialization

- Steel slag color sand, stone paint, putty powder, modified mineral powder, etc.

- Production of high-performance composite mineral admixtures by multi solid waste collaborative cementation

- Separation, grinding and modification of fly ash

Replacement of silica fume, ultra-fine limestone powder, ultra-fine silica fume and other water reducing agents and mineral admixtures by fly ash - Fly ash can replace carbon black, silica, calcium carbonate, quartz powder and other inorganic fillers

- A variety of industrial solid waste preparation of stone plastic and inorganic stone products

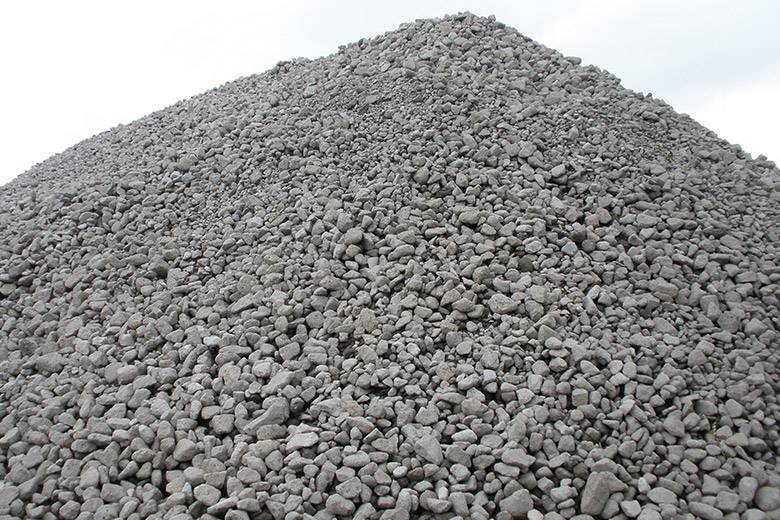

Solid Waste Processing Technology

Steam Jet Mill

Steam Jet Mill(Steam kinetic energy mill) Upgraded by conventional jet mill, adopts unique high-temperature mechanical sealing technology…

Classifying and Ball Mill Production Line

According to the principle of superfine ball milling classification, through redesigning and arranging the traditional ball mill lining plate, grinding body and…

Modification and Coating Process

Surface modification with important practical significance to improve the properties of the powders, increase the practical value and develop the application fields.

Academy

Application technology of ultrafine fly ash

2026-01-06

Ultrafine fly ash, in particular, performs well overall, showing improvements in both strength and…

Steel slag resource utilization: recycling scrap steel, paving roads, making cement… what other new pathways are there?

2025-12-04

Steel slag is a solid waste formed during the steelmaking process through high-temperature…

How to deal with steel slag as a usable resource

2025-10-10

A portion of the slag is returned to blast furnaces and sintered as a flux. However, the…

Turnkey Project

The key links are controlled at all levels, integrating R & D, design, production, sales and service, greatly shortening the construction period, saving investment costs, reducing investment risks, and benefiting from early production. Give you VVVIP experience.

Fully Customized Service

100 senior engineers provide advanced “one-stop” solutions and customized services for 3000 + enterprises all over the world.

After Sales Service

Higher than the same industry quality, reasonable price, all-round follow-up after-sales service, escort you.

Contact Us

You can email us

24-Hour Consultation Hotline

Head office Address

No. 168 Wenhua Road, Anqiu, Weifang City, Shandong Province, China

Please tell us what you need

Our engineers will contact you within 12 hours and provide free proposal and quotation.