Equipment & Technology

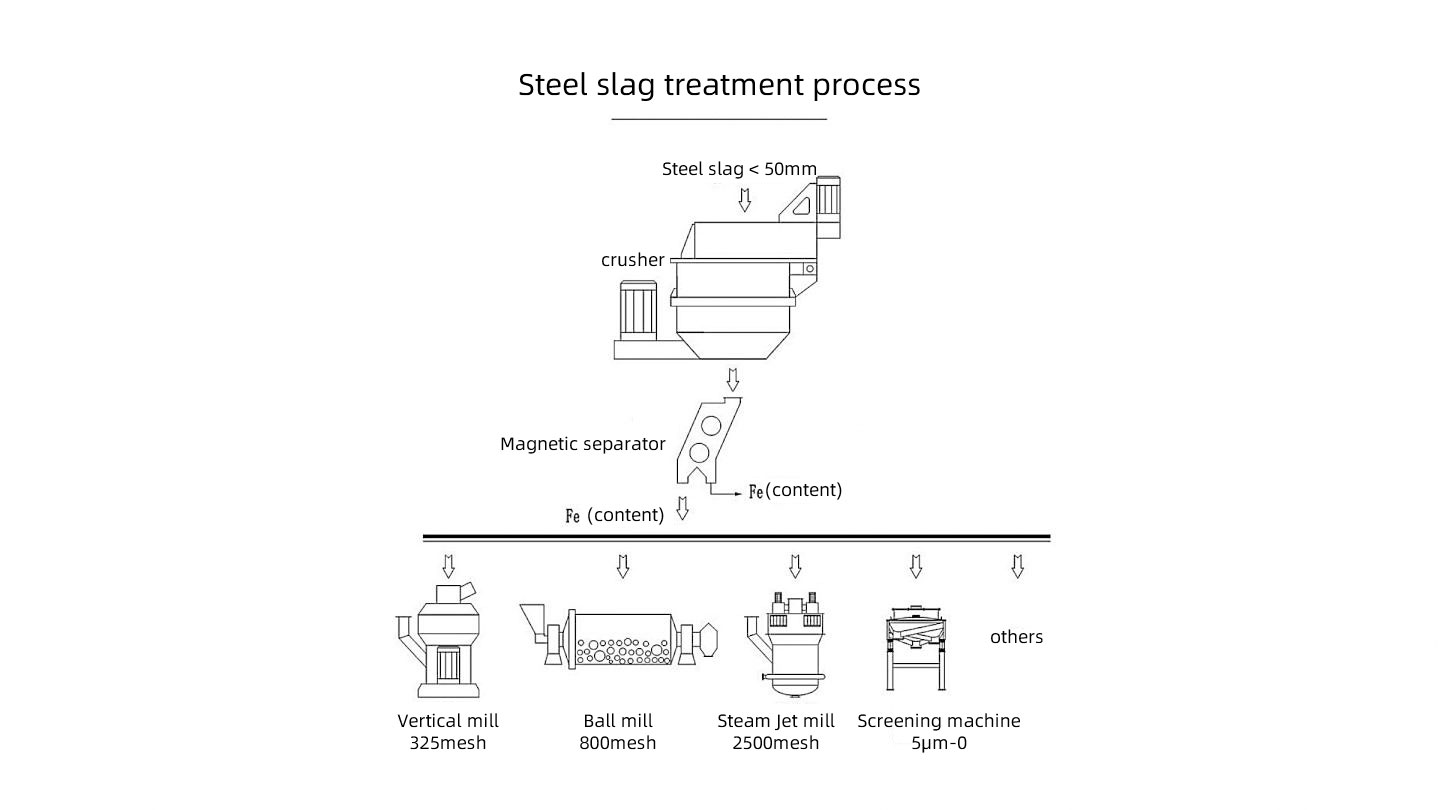

Crushing iron separation

The fineness is adjustable

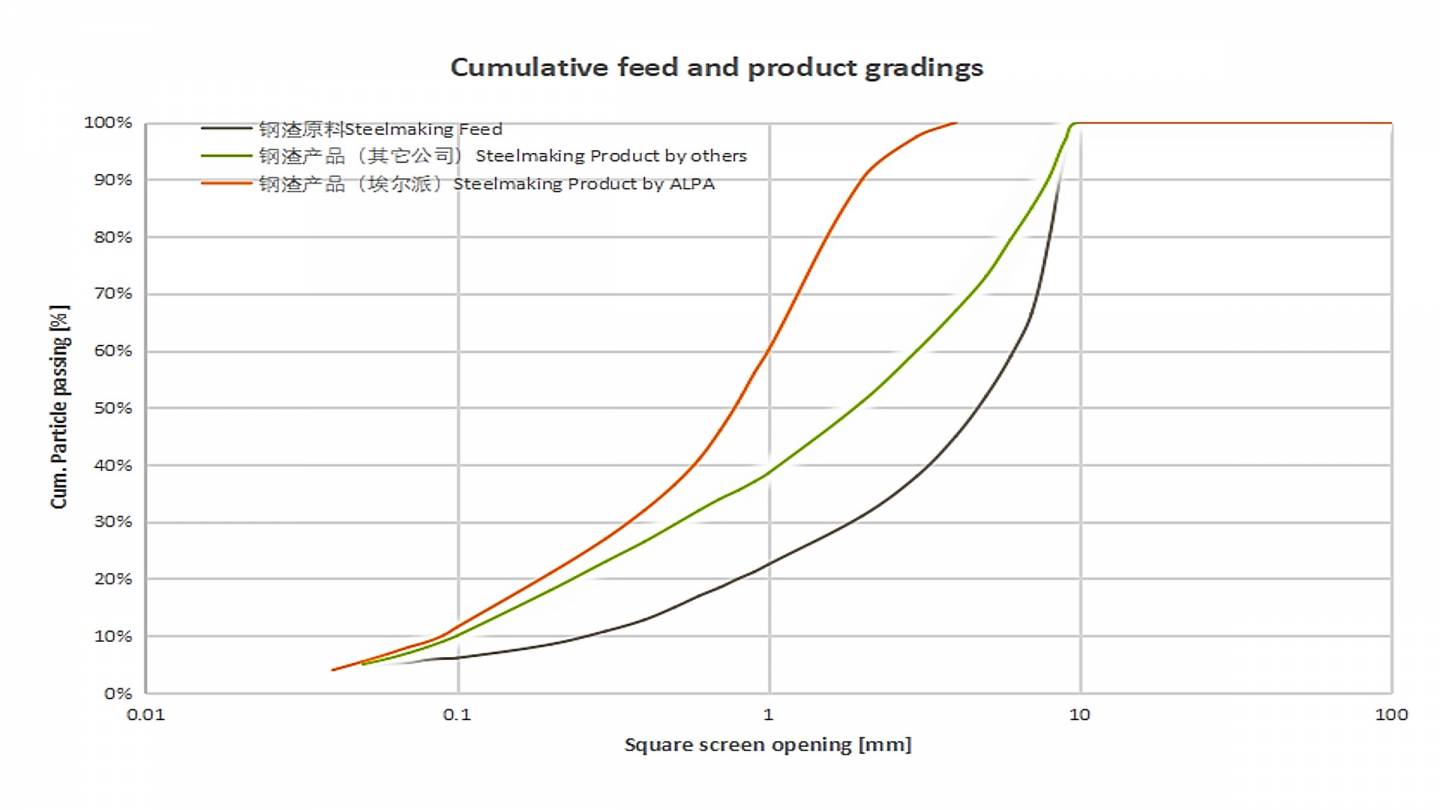

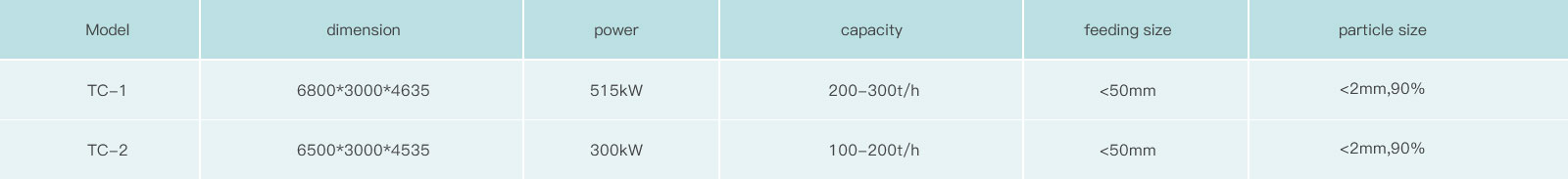

The steel tailing slag after crushing and iron separation or the steel slag after primary block steel crushing by dregs is produced by ALPA impact crusher manufactured by German technology. The maximum size of the steel tailing slag is 50% less than 50mm, and the maximum size of the steel tailing slag is 50% less than 1mm, 90% less than 2mm, and 100% less than 5mm. The fineness can be adjusted. The output per unit hour can be selected from 70-400 tons, and the energy consumption per ton is only about 2 kWh.

High selection rate

The crusher has high selective crushing degree and fine material. After crushing, the metal iron is selected by low intensity magnetic separation. The selected grade can reach 85% and the selected rate can reach 80%. The iron content of tailings can be reduced to 0.5% after beneficiation.

High activity and grindability

High intensity magnetic separation can be used to separate part of iron oxide and RO phase. After magnetic separation, the inerts of the fine slag powder are reduced, and the activity and grindability are improved, which provides favorable conditions for subsequent processing and application.

Technical Advantages

- The crushing ratio is large and the energy consumption is low. Taking steel slag as an example, the feed particle size can be less than 50 mm, the product particle size can be less than 2 mm, and the product energy consumption can be less than 2 kWh/t;

- Selective crushing, the crushing process can effectively dissociate metal and non-metal substances, making the magnetic separation process more simple and efficient;

- The wearing parts have long service life and easy replacement. The hammer head and lining plate are made of imported wear-resistant alloy and processed by special treatment;

- Humanized design, convenient maintenance. The top cover and power assembly can be overhauled 180 degrees by hydraulic lifting device;

- Reliable lubrication system. All bearing systems are lubricated with thin oil from oil station, and oil temperature and flow are equipped with automatic monitoring device;

- Excellent shock absorption effect. The rubber spring is installed between the upper and lower bodies, which can effectively absorb the vibration during operation.

Contact Us

You can email us

24-Hour Consultation Hotline

Head office Address

No. 168 Wenhua Road, Anqiu, Weifang City, Shandong Province, China

Please tell us what you need

Our engineers will contact you within 12 hours and provide free proposal and quotation.