industry market background

Self - gelling or auxiliary gelling material

Self-cementing or auxiliary cementing materials can replace or save M series masonry cement, PC series composite Portland cement, etc., widely used in a variety of industrial and civil building materials.

Market Background

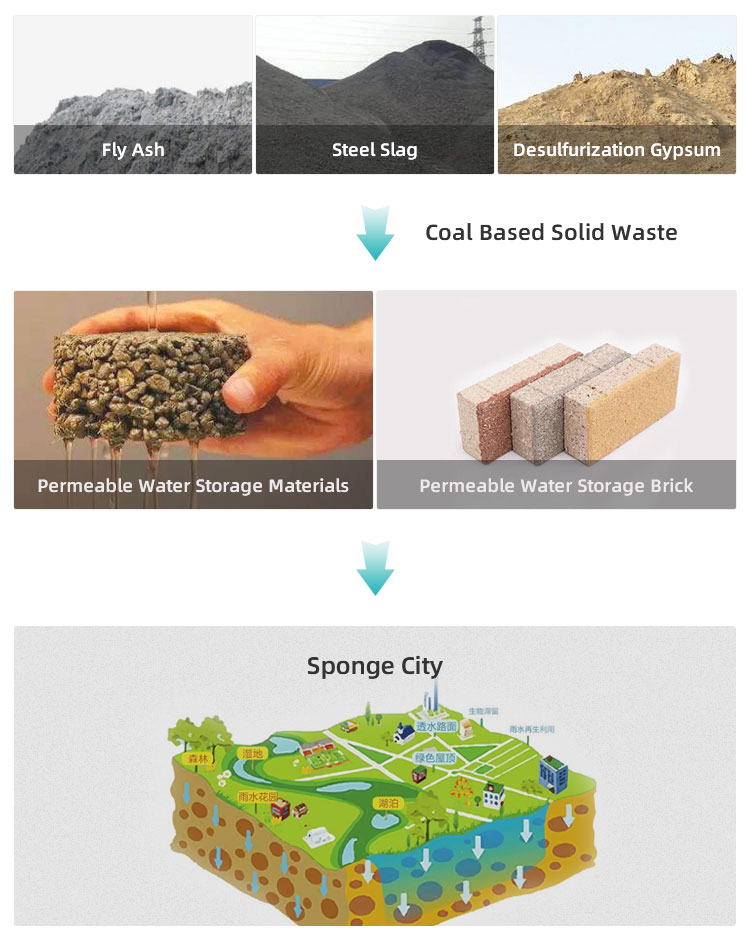

The State Council issued the Guiding Opinions on Promoting the Construction of sponge cities, requiring that more than 80 percent of sponge cities be built nationwide by 2030.

- The construction of sponge city needs a lot of inorganic permeable water storage materials.

- Coal based solid waste is the main raw material of inorganic permeable water storage materials.

- The national demand for inorganic permeable water storage materials is 5.3 billion m³.

- The market demand is 300 billion.

5.3billion m³

The national demand for inorganic permeable water storage materials

300billion

The market demand

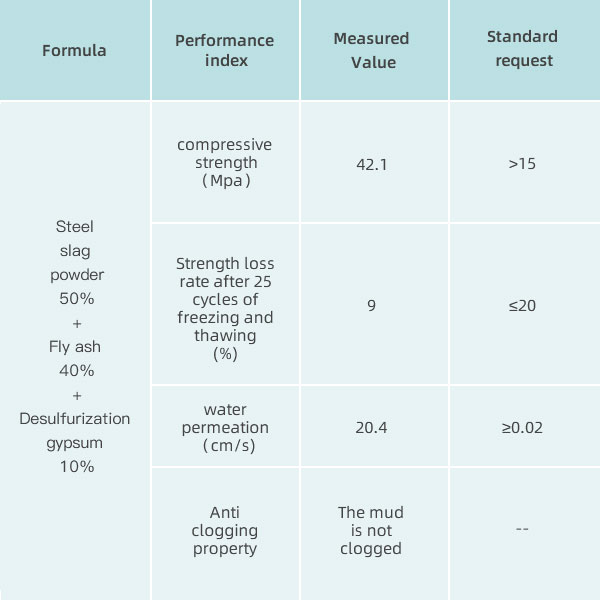

Innovative Technological Ideas to Fill The Gaps

Raw Material

Steel slag powder + fly ash raw material + desulfurization gypsum, 100% solid waste.

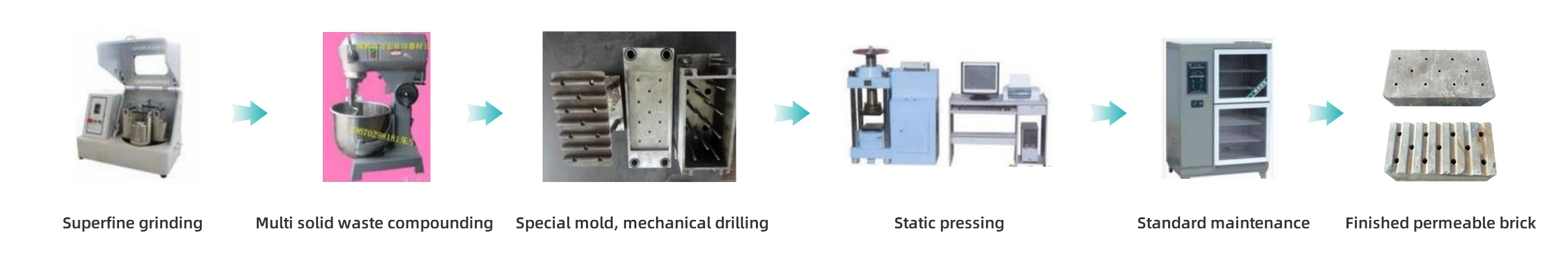

Process Equipment

Mechanical hole-making - static forming + hydrothermal curing

Product Performance

High strength + high water permeability + high abrasion resistance + anti-clogging + freeze-thaw resistance.

Application of Self - gelling or Auxiliary Gelling Material

Since the gel or auxiliary cementitious materials can replace or save M series masonry cement, PC series composite Portland cement and so on, are widely used in industrial and civil architecture really stone paint (instead of some organic emulsion), putty powder, masonry and plastering mortar, bedding and backfill concrete, wall materials and fabricated parts, brick block, inorganic stone slab (instead of natural stone, artificial stone, brick of pottery and porcelain, etc.), stone series, all kinds of PC components, etc. In particular, it can be prepared into a variety of prefabricated building materials and sponge city water permeable materials, ultra-thin and high strength inorganic stone plates (instead of natural stone and ceramic plates), UHPC ultra-high performance concrete components.

Experimental brick machine made in our own plant

It is superior to the national standard in terms of pore forming rate, static pressure loss, water permeability, etc.

The national standard (GB / T 25993-2010) is implemented. Water cement ratio is 0.2, molding pressure is 20MPa, curing temperature is 20 ℃ and humidity is 98%.

Innovative technology and equipment -- pressure controlled foaming machine

Pressure controlled foaming can significantly improve the strength and achieve “light and high strength”.

- The solid waste-based ultrafine powder is foamed to prepare porous materials, which can be used in building insulation materials, adsorption materials and sound-absorbing materials, etc., and the application prospect is very broad;

- Development direction: “Ultra light, high strength, high toughness, adjustable hole structure”;

- Support prefabricated building materials, with a market capacity of trillions.

Micro pressure foaming experimental device

Pressure foaming scale up experimental device

Conventional foaming / hot pressing foaming

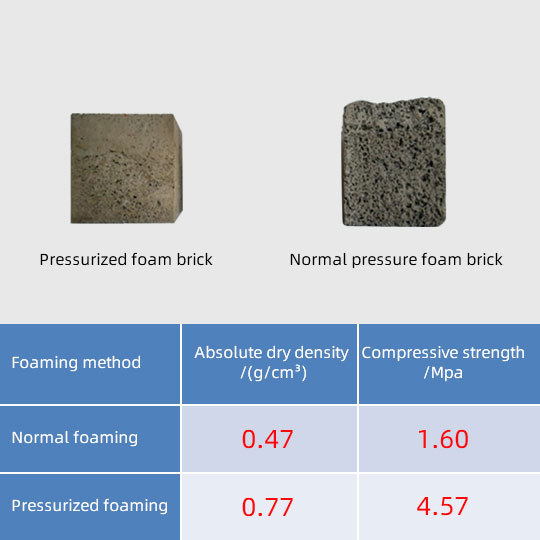

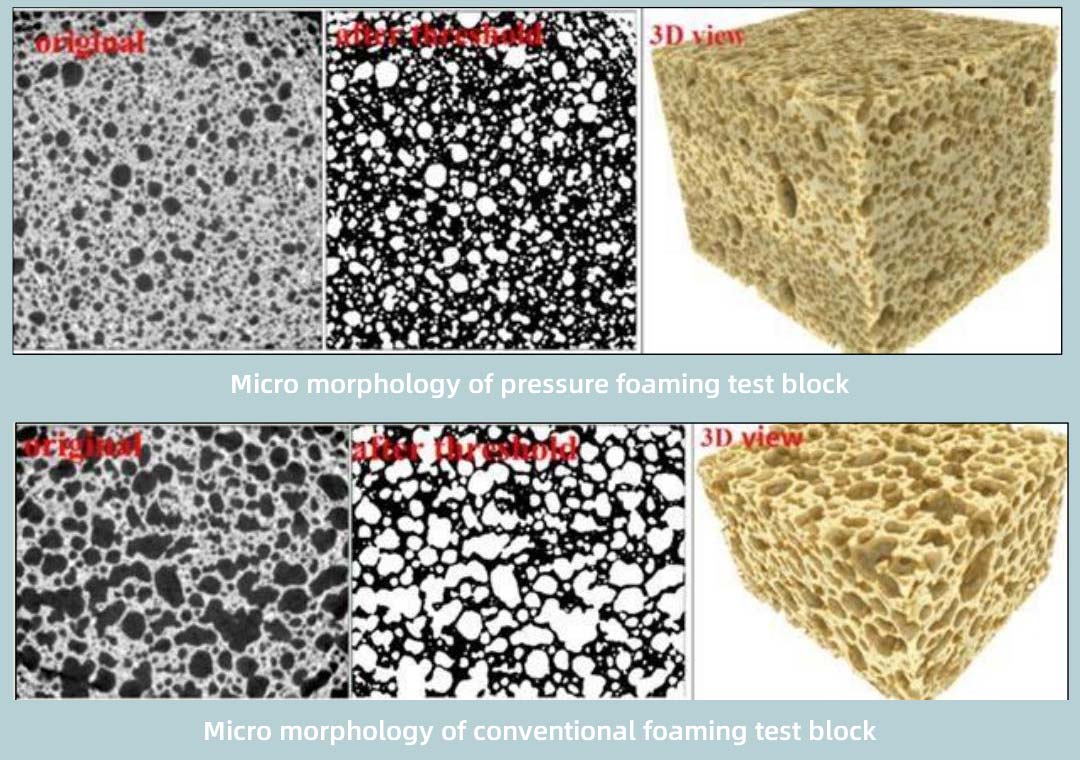

Product characteristics difference between pressure foaming and conventional foaming

The results show that the pressure foaming test block has relatively independent spherical pores, and the conventional foaming test block has connected irregular pores.

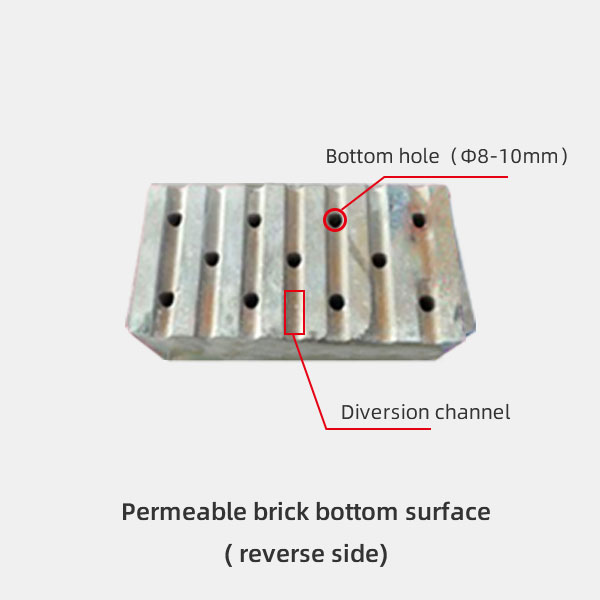

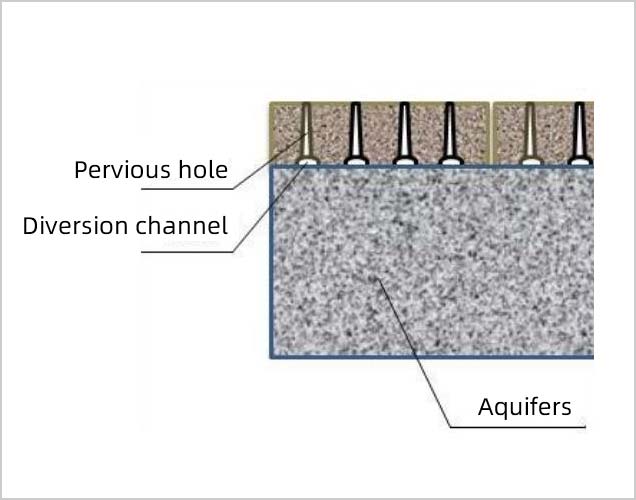

Combination design of permeable material and water storage material

The construction cost can be reduced by 2 / 3, the urban waterlogging problem and urban heat island effect can be effectively solved, and the recycling of urban construction waste can be realized.

- The upper part can pass through and the lower part can keep water, to simplify the construction;

- Permeability coefficient: 0.5cm/s;

- water storage rate: 600kg / m³。

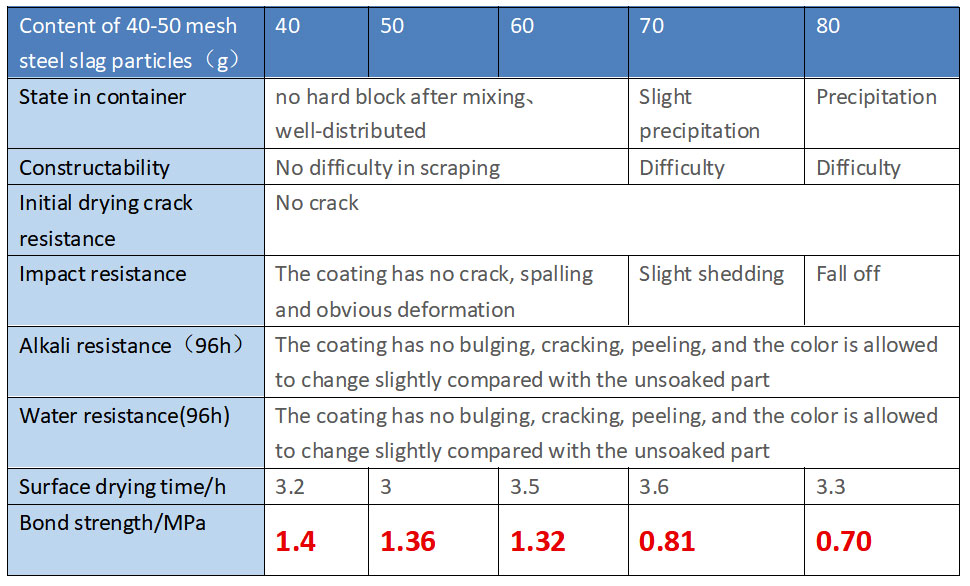

Solid waste composite cementitious putty powder

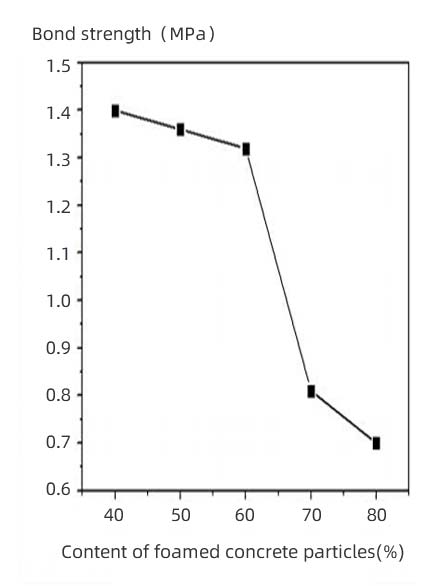

When the content of steel slag particles reaches 80%, the performance indexes of stone like paint are better than and meet the requirements of national standard. With the increase of steel slag particle content, the bond strength of stone like paint decreases.

- The putty powder is mainly used for indoor and outdoor plastering, and the domestic market is nearly 100 million tons / year.

- The putty powder is mainly composed of natural sand and cement in proportion. The production cost is about 800 yuan / ton, and the market price is 1200-1500 yuan / ton.

- Using industrial solid waste steel slag composite powder instead of cement and natural sand to prepare putty powder can reduce the production cost by 30-50%, and the market capacity is more than 100 billion yuan.

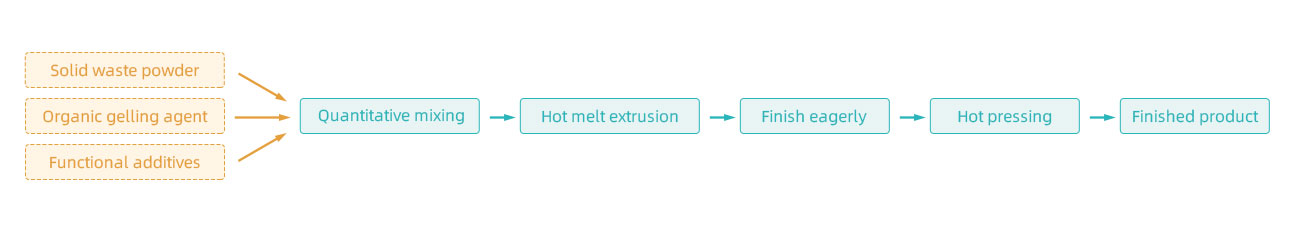

Stone plastic products

Industrial background of stone plastic series products

- Solid waste powder + PVC + additives to synthesize home decoration materials, replacing wood, ceramics and composite boards;

- Waterproof, mothproof, flame-retardant, formaldehyde-free, wear-resistant, non-slip, health care, heat preservation, sound insulation;

- The market capacity is as high as 1,000 billion, the market has just started, and all products are currently exported;

- Solve the “zero formaldehyde” problem of products in the home decoration market.

Advantages of stone plastic series products

- The cost of raw materials is reduced by more than 20%;

- The equipment area is reduced by 2/3;

- Project investment reduced by more than 70%;

- Increase production capacity by more than 30%;

- The overall economic benefit is increased by more than 40%.

Innovative technology equipment for the whole system of stone plastic products

Contact Us

You can email us

24-Hour Consultation Hotline

Head office Address

No. 168 Wenhua Road, Anqiu, Weifang City, Shandong Province, China

Please tell us what you need

Our engineers will contact you within 12 hours and provide free proposal and quotation.