Annual output of 500,000 tons of solid waste construction plaster project

1. Project Background

Using solid waste to prepare building plastering products has the characteristics of large solid waste consumption and high added value. The main solid wastes include: steel slag particles and steel slag superfine powder. The product is building plastering material. The product can be widely used in building masonry plastering, and its added value can be as high as RMB 600 / T solid waste, showing good economic and social environmental benefits.

2.Project Design Scheme

2.1 Production Scale

The annual production of solid waste building plastering material is 500,000 tons.

Annual production time: 6,000 hours.

2.2 Raw Material

There are three kinds of raw materials for the project: 340,000 tons of steel slag particles, 80,000 tons of steel slag ultra-fine powder and 80,000 tons of composite cementitious materials.

Total raw materials: 500,000 tons.

2.3 Products

Solid waste construction plastering material: 500,000 tons/year. The product is mainly used for building masonry plastering.

2.4 Production Process Technical Plan

2.4.1 Production Technology and Process

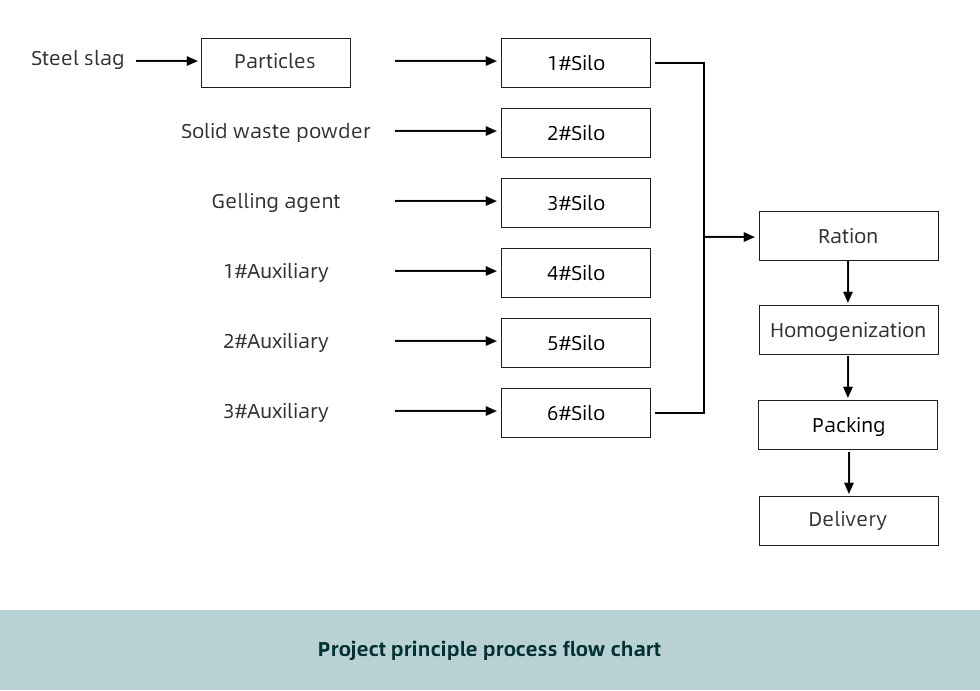

The overall process technology of the project is described as follows: with steel slag superfine powder, inorganic cementitious material and organic cementitious material as raw materials, qualified products are produced through “raw material pretreatment – quantitative feeding – raw material homogenization – packaging” and other processing procedures.

2.4.2 Main Equipment System

The process equipment system of this project mainly includes:

(1) Raw material buffer system;

(2) Raw material pre-processing system;

(3) Raw material quantitative feeding system;

(4) Raw material homogenization system;

(5) Packaging system;

(6) Central control system

The overall process diagram of the project is as follows:

2.5 Project Area

2.5 Project Area

The total area of the project is 3000 square meters.

2.6 Construction Conditions

1) Power consumption: The total installed capacity of this project is about 500kW, and the annual power consumption is 2.5 million kWh.

2) Water consumption: the production water consumption is 0 million tons / year.

3) Transportation: The existing roads can meet the transportation of raw materials and finished products.

3. Environmental Protection

Electricity is used as the energy medium in the production of this project, and there are no pollutants such as sewage, flue gas and solid waste in the production process.

4.Project Schedule

The construction period of the project is 6 months, including 3 months for engineering design and equipment procurement, 2 months for on-site construction, installation and commissioning, and 1 month for trial production and commissioning.

5.Personnel Arrangement

A total of 20 people. Including, quality inspection: 2; loading and unloading workers: 6, inspectors: 6,and 6 people for other public auxiliary personnel.

6.Investment Estimation

The fixed asset investment of the project is estimated to be 35 million yuan, of which 21 million yuan is for equipment investment, 10 million yuan for civil construction and installation, and about 4 million yuan for other investment.

7.Benefit Analysis

7.1 Annual sales revenue: 250 million yuan/year

After the project is fully put into operation, the normal annual output is 500,000 tons of construction plastering materials, and the product sales price is 500 yuan/ton (market price 500-1200 yuan/ton), and the annual operating income is 250 million yuan.

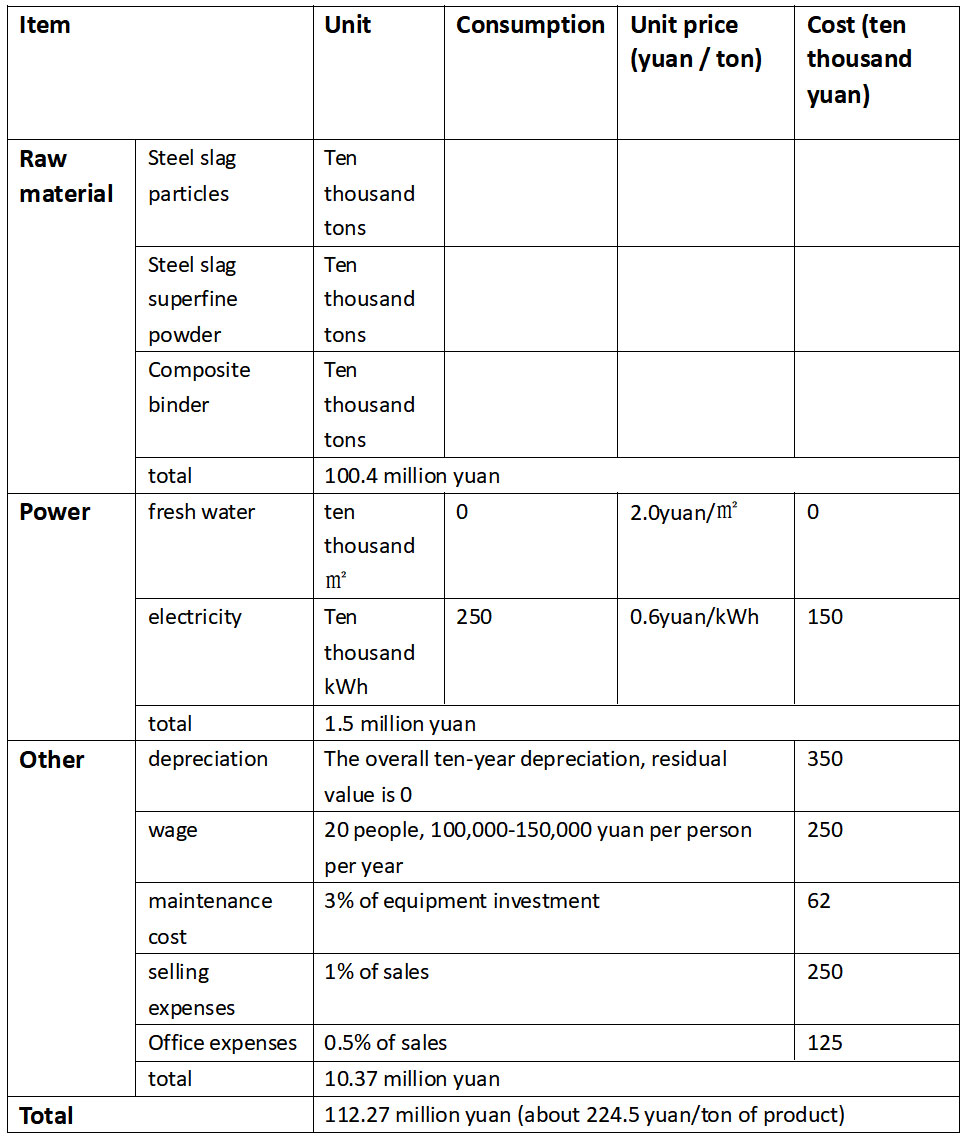

7.2 Total annual cost: 112.27 million yuan

The annual total cost mainly includes power consumption, labor, sales, management, depreciation and maintenance, with a total of 112.27 million yuan. The cost structure is as follows.

7.3 Annual profit and tax analysis

7.3 Annual profit and tax analysis

After the completion of the project, the annual sales revenue is 250 million yuan, the annual operating cost is 112.27 million yuan, the annual profit and tax is 137.73 million yuan, and the investment is recovered in one year.

八、In Conclusion

After the project is put into operation, 500,000 tons of solid waste building plastering materials are produced annually. The products are used for building masonry plastering, with huge market capacity and smooth sales channels. The investment of the project is 35 million yuan, the annual solid waste treatment is 420000 tons, the annual output value is 250 million yuan, and the new annual profits and taxes are 137.73 million yuan, which has significant economic and social environmental benefits, and the project is feasible.