High value utilization

of fly ash-based inorganic filler

With the further improvement and development of technology, the market of fly ash-based inorganic filler is huge and has infinite potential

Market introduction

The development of fly ash-based inorganic fillers is an important direction for the green and high-value utilization of fly ash in the future. Especially in recent years, it has become the focus of various universities and research institutes. However, due to the requirement of fine particle size of inorganic fillers, high energy consumption of ultra-fine grinding of fly ash, lack of economy, and lack of good modification technology to make fly ash reach the functional high value of various inorganic fillers, there has been no industrialization for many years. After years of research and development, we are the first in the world to break through the low-cost ultra-fine grinding, grading and functional high value-added modification of fly ash, and the first to achieve industrial operation. With the further improvement and development of this series of technologies, the inorganic filler based on fly ash will be of great potential in the market.

At present its main market application has the following several aspects

1.Replace a large number of inorganic non - metallic mineral fillers

It mainly replaces a large number of inorganic non-metallic mineral fillers, such as calcium carbonate, kaolin, talc, quartz, feldspar, wollastonite, limestone, alumina, magnesium oxide, magnesium hydroxide, aluminum hydroxide, silica, carbon black, phosphorous flame retardants and so on.

2.As a green high performance ultra-fine admixture or mineral admixture or water reducer

Mainly replace cement, ore powder, silica fume, ultrafine silica powder, ultrafine limestone powder, etc., used in cement, commercial mixing, PCUHPC and other building materials, in order to reduce costs and improve performance. Especially in the large volume, self-compacting, high strength, high performance, special concrete use effect is more obvious.

3.Applications in other high value-added fields

Using fly ash microbeads instead of alumina powder to make ceramic membrane and using its spherical microbeads as pore-forming agent can get better filtration effect and greatly reduce the cost of raw materials.

Using the hollow, microporous and spherical characteristics of fly ash microbeads, it can be used for heat preservation, noise reduction, light body, adsorption material or carrier, etc.

Replace a Large Number of Inorganic Non-metallic Mineral Fillers

As a kind of chemical filler, it mainly replaces a large number of inorganic nonmetallic mineral fillers. Such as calcium carbonate, kaolin, talc, quartz, feldspar, wollastonite , limestone, alumina, magnesium oxide, magnesium hydroxide, aluminum hydroxide, silica, carbon black, phosphorus series flame retardants, etc., used for:

High polymer material

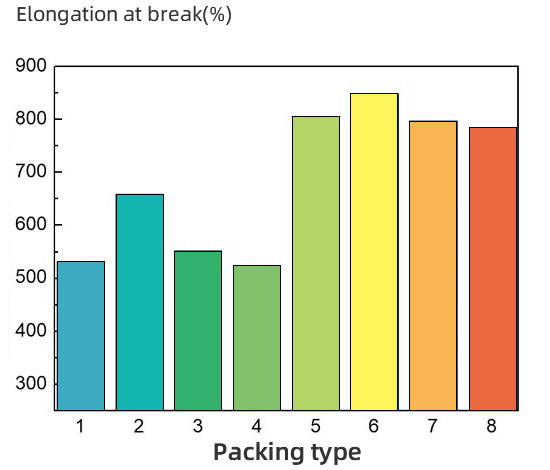

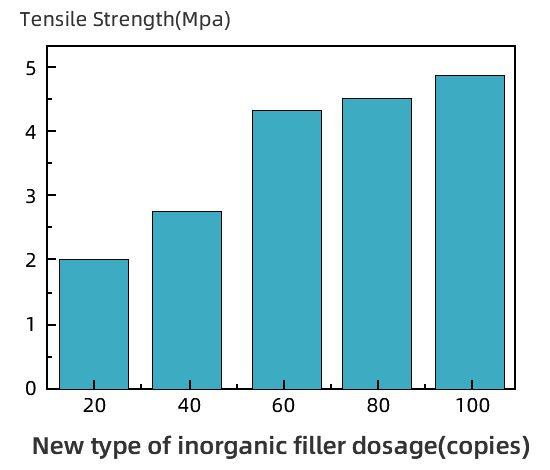

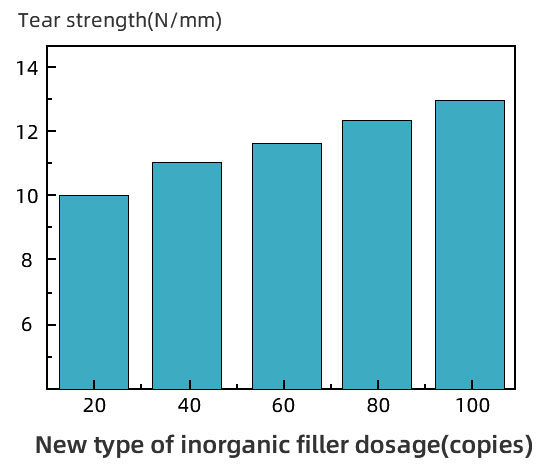

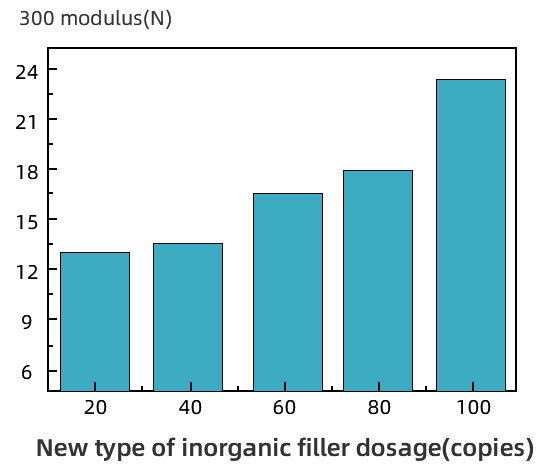

Such as all kinds of plastic, rubber, plastic elastomer, polyurethane elastomer, wire and cable, synthetic leather, adhesive, etc.

Ceramic material

Such as artificial wear-resisting corrosion resistant marble, granite, floor tiles, etc.

Composites

Such as fiberglass, wood plastic, linoleum waterproof and so on.

Paper material

Such as a variety of fire-resistant, corrosion resistant, wear resistant, water resistant, tear resistant, high rigid special paper, wrapping paper, corrugated paper, cartons, etc.

Paint

Such as anticorrosive paint, wear - resistant floor paint, wear - resistant corrosion - resistant high temperature coatings.

According to incomplete statistics, in 2016 the domestic consumption of more than 15 million tons of calcium carbonate (not including desulfurization and feed grade), feldspar, quartz, kaolin, bentonite and other clay minerals more than 30 million tons, more than 8 million tons of carbon black, silica, plus a variety of other organic and inorganic, natural and artificial functional filler aggregate demand of more than 60 million tons, with greening, points out, the developing trend of functional materials, the dosage of the packing will be greater and greater.

According to the preliminary investigation and analysis, technical evaluation and the prospect of follow-up research and development, fly ash can gradually replace various conventional natural or artificial fillers at a ratio of 10-20% in the next five years, with a total capacity of 5-10 million tons. As a common chemical filler, calcium carbonate has a wide range of applications and low price. Its fineness is mainly 10 microns. The average price of tons is about 1000 yuan for heavy calcium and 1200 yuan for light calcium. With the same fineness of fly ash ultrafine beads replacing calcium carbonate, the performance indexes of various products have been improved, and the cost has been significantly reduced. Therefore, it has great potential to replace calcium carbonate in the field of dark products.

As a Green High Performance Ultra-fine Admixture or Mineral Admixture or Water Reducer

As a kind of green high performance super fine admixture or mineral admixture or water reducer, mainly replace cement, ore powder, silica fume, ultrafine silica powder, ultrafine limestone powder, etc., used in cement, commercial mixing, PCUHPC and other building materials, in order to reduce costs and improve performance. Especially in the large volume, self-compacting, high strength, high performance, special concrete use effect is more obvious.

Mainly due to this series of products specific surface area of up to 700-3000 ㎡/ kg, cement fineness ratio and S95 mineral powder, thin, more than silica fume spherical degree is high, such as liquidity, good dispersion, and the main chemical composition is active silicon oxide, activated alumina, active calcium oxide, etc., in the concrete system, on the one hand, fill, lubrication, flocculant solution, dispersion, density, such as physical function, On the other hand, the product of the active silicon oxide, activated alumina and active oxide with precipitation of calcium hydroxide crystal of the cement hydration and hydrated calcium silicate gel gelling materials, such as aggregate into the effective alkali, sulfate and chloride ion strength and durability of cement and concrete, such as the harmful material up chemical reaction, generate good for cement and concrete strength and durability of silicon calcium aluminate gel and other beneficial compounds, in the role of two aspects of physical and chemical, to improve the workability of fresh concrete, such as: good liquidity, good water retention, no bleeding, no segregation, slump loss is small, pump, etc.

It can improve the bonding degree between slurry and aggregate interface, reduce the pores of hardened concrete, reduce the pore size, compact structure and volume stability, enhance the ability of concrete to resist various chemical attacks and inhibit alkali aggregate reaction, and significantly improve the durability of cement paste and concrete.

Products in the active silicon oxide, activated alumina composition combined with calcium hydroxide, effective alkali and sulfate, chloride and other adverse to the durability of concrete material, to alleviate some of concrete durability of chemical reactions or other adverse effects.

Reduce the peak temperature of the concrete internal temperature rise, reduce the risk of large volume concrete cracks.

Improve hardening concrete structure compactness, refine pore, difficult and harmful pore porosity, reinforced concrete itself to the intrusion of harmful substances, infiltration, diffusion defences, protected from outside invasion medium steel from corrosion and rust.

Improve the fresh concrete rheological properties, secrete water and segregation phenomenon, and can keep certain workability, in order to reduce water consumption and good create conditions for the durability of concrete structure.

This series of products as a kind of high performance concrete mineral admixture, main uses:

Green high performance concrete mixed material and superfine admixture of concrete

Green and high-performance 52.5 cement is produced by mixing 40%-50% of grade 52.5 cement; Use 20%-30% of grade 42.5 cement to produce green and high-performance 42.5 cement; Green and high-performance 32.5 cement is produced by mixing 20%-25% of grade 2.5 cement or mixed cement.

Mineral admixture of concrete resistance to chloride ion erosion

It is used to prepare C30-C100 concrete which is seriously eroded by chloride ion in harbors, wharves and roads in frigid areas.

Autoclave prestressed concrete mineral admixtures

Used for the preparation of C40-C120 high – speed rail sleeper board, pipe pile, mesh, electric pole, TRC board, GRC board, culvert pipe and other prestressed concrete.

Anti-abrasion concrete, mineral admixture

Used for the preparation of C30-C100 airport runway, expressway, spillway and other high abrasion concrete.

Anti-radiation mineral admixture of concrete

It is used to prepare the nuclear island containment vessel of C30-C100 nuclear power plant, hospital and other nuclear radiation concrete.

Cracked concrete mineral admixtures

Used for preparing C30-C100 concrete with dry air and poor temperature difference between day and night.

Resistance to carbon dioxide gas mineral admixture of concrete

Used to prepare concrete with high carbon dioxide concentration of C30-C100.

Self-compacting concrete mineral admixtures

Used for preparing C30-C100 non – vibrating concrete.

Concrete mineral admixtures

Used to prepare C30-C100 non – stucco finish concrete.

The bionic mineral admixture of concrete

Used to prepare landscape concrete for growing plants.

Mineral admixture of concrete resistance to sulfate erosion

Used for preparation of C30-C100 subway, tunnel, sewage pipe, underground engineering and other concrete with severe sulfate erosion.

With the improvement of ecological civilization construction and environmental protection requirements, on the one hand, the price of cement and ore powder is increasing day by day, while the market capacity base of traditional cement and commercial mixture is huge. Therefore, using fly-ash based coal power solid waste ultra-fine fillers to replace ordinary cement and ore powder has huge market potential and economic benefits. On the other hand, with the rise of prefabricated building materials and green high-performance concrete, the market potential of replacing mineral additives such as silica fume is huge and the benefits are remarkable. At present, the market price of silica fume is more than 2000 yuan per ton. Replacing silica fume with fly ash microbeads can significantly reduce the cost of high-performance concrete and improve its performance, with remarkable benefits.

Other High Value-added Applications

Using fly ash microbeads instead of alumina powder to make ceramic membrane and using its spherical microbeads as pore-forming agent can get better filtration effect and greatly reduce the cost of raw materials. Using the hollow, microporous and spherical characteristics of fly ash microbeads, it can be used for heat preservation, noise reduction, light body, adsorption material or carrier, etc.

Brief Introduction of Products, Processes ,

Investment and Benefits

Fly ash ultra-fine Beads

The raw ash is pre-sorted to get first grade ash or fine ash, and then the super fine beads are obtained from the first grade ash by a special super fine classifier. The remaining coarse products can be used as high quality second grade ash.

Composite mineral admixture (superfine admixture)

Production process: through the ball mill liner, grinding body, material discharging device to redesign and combination, so that the transformation of the traditional ball mill into a special ultra-fine ball mill...

Contact Us

You can email us

24-Hour Consultation Hotline

Head office Address

No. 168 Wenhua Road, Anqiu, Weifang City, Shandong Province, China

Please tell us what you need

Our engineers will contact you within 12 hours and provide free proposal and quotation.