Compound mineral admixture

(superfine admixture)

Brief introduction of production technology, nvestment and benefits

Operation Technology

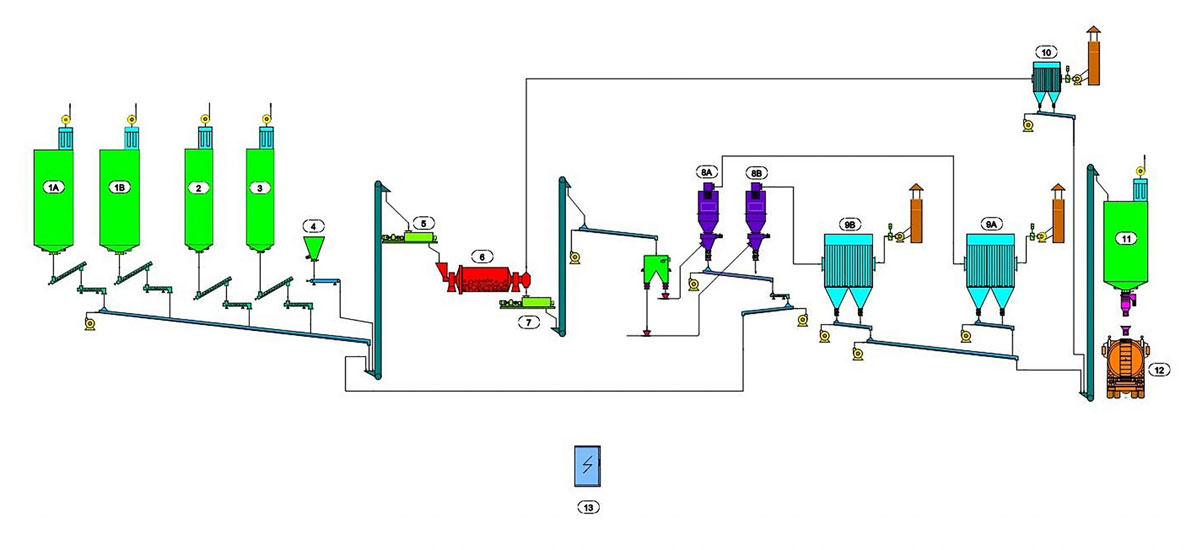

Redesign and permutation and combination of ball mill liner, the grinding body, discharging device make traditional ball mill upgrade into ultrafine special ball mill, and form a complete set of special superfine grading system, under the reasonable formula, the use of low-cost processing with solid waste more stimulating technology, make the coal fly ash, slag, steel slag, slag furnace bottom, desulfurization gypsum and other industrial solid waste into high strength high performance composite mineral admixture with high added value products. Thus, the added value and consumption of solid waste processing and utilization are greatly increased, and the cost and performance of cement and concrete are reduced.

(Ball mill plus Air classifier closed loop cycle negative pressure system, or open circuit ball mill system.)

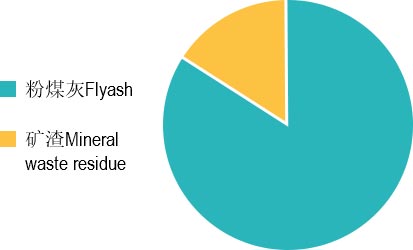

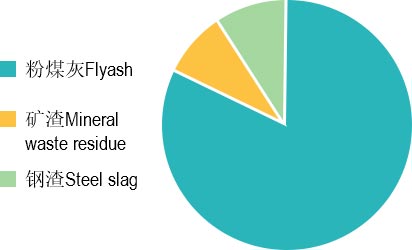

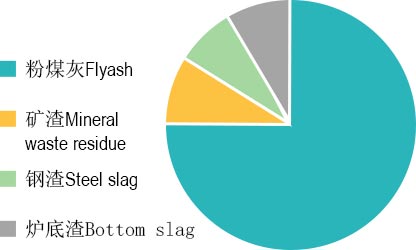

Basic Recipe

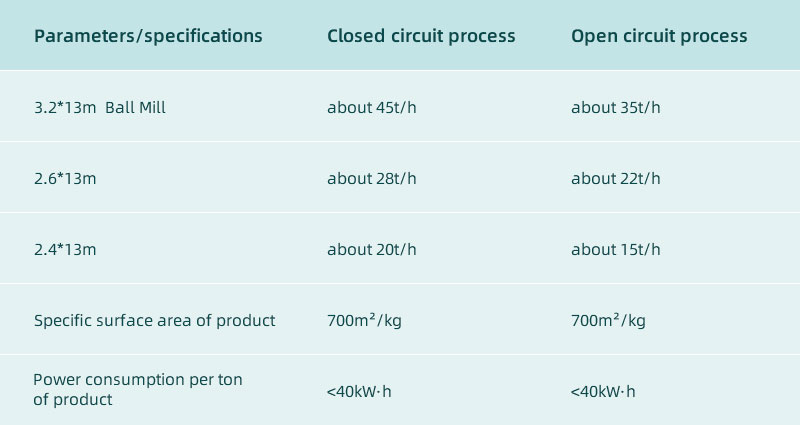

Common Production Line Construction Scale & Performance Index

Technical Characteristics

Superior performance

The product performance meets the secondary grinding slag index of Mineral Admixtures for High Strength and High Performance Concrete GB/T 18736-2017.

Benefit is remarkable

Increase the amount of fly ash and steel slag, reduce the amount of clinker or cement, reduce the production cost of cement concrete and improve the performance.

Small investment, quick effect, good environmental protection

The open-circuit technology only needs to renovate the old mill with low investment, short time limit and quick effect. Closed-circuit processes add a grading system, more than 30% more than open-circuit production capacity, also more environmentally friendly and energy efficient.

Scope & Object of Adaptation

This technology is suitable for the transformation and upgrading of cement grinding station idle mill and reuse.

The technology is suitable for use in cement, mineral powders price is high, fly ash, steel slag and other industrial waste residue resource-rich regions.

The product is especially suitable for high strength high performance concrete prefabricated parts, special cement, and other products.

Application scenarios

Fly ash or mineral powder grinding and processing enterprises

- Will be processed into high performance composite mineral admixture of fly ash, the sales price can be much higher than ordinary grinding fine fly ash;

- Mineral processing into high performance composite mineral admixture, sales cases can significantly reduce the cost of the same price;

Cement enterprises

- Products can be used as cement mixed material, with the strength grade of cement can be more mixed mixed material by more than 20%, reduce the cost of more than 20 yuan/ton;

- Transformation can produce concrete with superfine admixture, sold to concrete mixing station;

Concrete enterprises

Based on the original formula of commercial mixing station, the cement dosage can be further reduced to reduce the concrete production cost of more than 10 yuan/cubic meter.

Industrial application

The technology has been used in many projects in Shandong, Anhui, Hebei, Guizhou, Shanxi and other regions, and the operation is good.