Metallurgical solid waste turned into 3D printing material

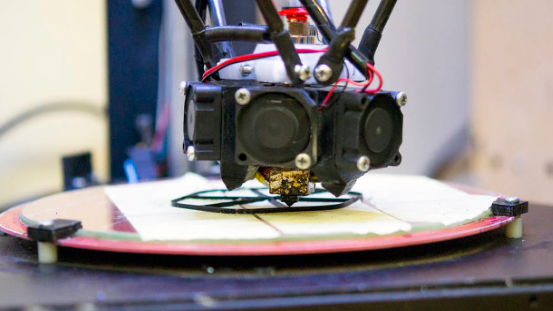

There are few types of materials and unstable performance, which seriously restricts the development and application of 3D printing technology. The R&D team of Wuhan Iron and Steel Co., Ltd. Technology Center uses metallurgical solid wastes such as silicon steel corner scraps and waste casting billets as raw materials, and prepares a series of iron-silicon powders for 3D printing through vacuum atomization, breaking the monopoly of foreign technology in one fell swoop and providing metallurgical services for iron and steel enterprises. Solid waste reuse opens up a new way.

Using iron-silicon powder as raw material can solve the problem that special-shaped materials in the 3D printing industry are not easy to produce, manufacture, and process.

Silicon steel is a unique steel type of WISCO and is famous for its high silicon content. Over the years, discarded silicon steel is usually re-smelted as raw material for the next batch of production to achieve on-site circulation.

Explore the economic value of silicon and develop products that meet the characteristics of WISCO. With this original intention in mind, in 2016, this innovative project was launched. With the continuous development and popularization of 3D printing technology, Chen Junfu noticed that the soft magnetic material iron silicon powder used for 3D printing can be completely extracted from silicon steel scrap. After a series of scientific investigations and experiments, Chen Junfu’s team used a vacuum atomization process to process silicon steel scrap into iron-silicon powder under non-oxidizing conditions.

At present, the technology has obtained a number of national patents, and the products have been widely used in 3D printing.