Fly Ash Quality Control Measures

Fly ash is the powder collected from the flue gas of pulverized coal furnaces in power plants. High-quality fly ash can improve the pumpability, slump loss of concrete mixture, reduce unilateral water consumption, etc., can reduce the heat of hydration of mass concrete, and improve the durability of concrete such as impermeability and chemical resistance. . Today, fly ash, as a kind of concrete mineral admixture, has become an indispensable important component and functional material in ready-mixed concrete.

Background information

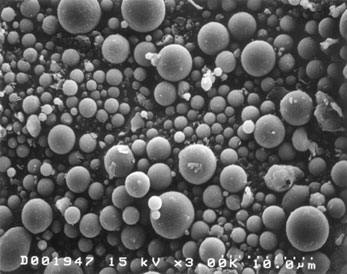

(1) Composition and effect of fly ash. Fly ash exists in the form of particles. Observed under a microscope, fly ash is a mixture of composite structures composed of glass microbeads, sponge-like vitreous bodies, and carbon particles. Fly ash has “morphological effect”, “activity effect” and “micro-aggregate effect”.

(2) The current situation of supply and demand of fly ash. With the deepening of the research and application of fly ash, the application technology of fly ash continues to mature. However, the power plant only treats fly ash as a kind of waste, and only considers meeting environmental protection requirements, and the quality of fly ash is often not guaranteed. In order to meet supply demand and pursue maximum economic benefits, fly ash suppliers buy everywhere, which leads to unstable sources, or artificially mixes or adds unknown impurities, which further increases the quality of fly ash. The quality of fly ash used in batching plants often fluctuates all the time.

(3) The technical indicators of fly ash in GB/T 1596-2017 include fineness, water demand ratio, loss on ignition, water content, sulfur trioxide, free calcium oxide, density, stability, activity index, etc.

For quick inspection, when the fly ash is inspected at the mixing station, the fineness and water demand ratio of each vehicle will be inspected first, and the inspection will be released first, and other indicators will be inspected later. In fact, speculative molecules can pass the post-processing method, resulting in that the fineness and water demand ratio of some fake ash will be qualified, and the subsequent inspection of other indicators may be unqualified, or the fresh concrete is found to have large slump and ammonia in actual production. Smell or bubbling and black oil phenomenon, etc.

Test methods and results

(1) Routine test indicators: according to GB/T 1596-2017.

(2) Color: Visual inspection and comparison.

(3) Particle morphology and vitreous body: observe with a microscope, magnify more than 100 times.

(4) Water demand ratio: The water demand ratio comparison test is carried out with the cement used for production and the benchmark cement.

(5) Inspection of ammonium salts: According to the reaction principle that ammonium salts can release gas in an alkaline environment, add an appropriate amount of NaOH solution to the fly ash and stir it evenly, observe for 5 minutes, and observe whether there are bubbles or irritating odors.

Quality Control Program

(1) The source of fly ash should be controlled before weighing. Check whether the manufacturer’s certification materials, vehicle GPS track and charging port are sealed and marked as required. If the certification materials are found to be incomplete or inconsistent, they will be firmly rejected.

(2) Ensure that the sampling is representative. First, use the sampler to sample the multi-tank mouths, and then carry out the fineness test after mixing the samples in the upper, middle and lower parts of the sampler evenly. Then carry out dynamic sampling, install a valve at the blowing port, and take samples at the beginning, middle and tail of the blowing process. If there is a significant difference with the quality of the sampler, stop or return the product immediately, and implement the supplier’s assessment procedure.

(3) Although the amount of fly ash is not particularly large, its quality has a great influence on the quality of concrete. It is recommended to carry out vehicle-by-vehicle inspection. There are many fly ash inspection items, and the comprehensive inspection takes a long time. The order of inspection items can be adjusted according to the color, particle shape, odor, and flow morphology of fly ash, and the corresponding key indicators can be selected for priority inspection, and the possible inconsistencies can be quickly screened out. Eligible items.

How to quickly and effectively control the quality of fly ash in a mixing plant has become a hot topic in the concrete industry, and technical workers in related fields have summed up some auxiliary control methods from production practice. From the confirmation of the source of fly ash and various sampling methods to strengthen the representativeness of the sample, on the basis of the inspection in accordance with the provisions of GB/T 1596-2017, the color, particle shape, odor and flow shape characteristics of each vehicle fly ash inspection are added. According to the results of the auxiliary inspection items, it is preliminarily judged that the index items may be affected, and the corresponding key indicators are selected for priority inspection in a targeted manner, and the possible unqualified items can be quickly screened out.