Annual production of 1 million tons of superfine steel slag powder project

1. Project background

Because steel slag has problems such as poor stability, low activity, and poor grindability, its application in cement and concrete is limited. While the superfine powder is one of the keys to improve its performance. Our company has long been engaged in the research and development of the comprehensive utilization of steel and metallurgical solid waste resources and equipment manufacturing. Based on years of research and practice, we have cooperated with the team of Professor Liao Hongqiang of Shanxi University to jointly develop the “steel slag ultrafine classifying and ball milling method to prepare steel slag ultrafine powder, high-performance composite mineral additives and high-performance modified mineral powder”, “New technology for preparing ultra-fine powder materials and steel slag wear-resistant particles by supersonic steam pulverization of steel slag”, “Preparing steel slag-based artificial colored sand from steel slag wear-resistant particles “, “The preparation of artificial marble and composite decoration materials from ultra-fine steel slag powder”, “The preparation of putty powder and real stone paint coatings from ultra-fine steel slag powder and steel slag-based artificial colored sand”, and “Preparation of sponge city water-permeable materials with ultra-fine steel slag powder” etc. This new technology, the technological achievement is the international frontier new technology, provides a new way for the comprehensive utilization of steel slag resources. The above-mentioned 6 technologies are relatively mature and reliable, and industrial production is already available or realized. Especially in the field of ultra-fine grinding of steel slag, fly ash, slag, and other bulk solid wastes, low-cost, large-scale, industrialized production has been realized, and the specific surface area can be adjusted between 600-2000.

Since the utilization of building materials is the main way of large-scale utilization of solid waste, the key technology is the deep activation of activity. And ultrafine powdering is an important way to deeply stimulate the activity of industrial solid waste. Therefore, according to the multi-solid waste synergistic excitation mechanism and low-cost ultra-fine processing technology, the reasonable organization formula can use steel slag, slag, fly ash, etc. to prepare high-performance composite mineral additives, water reducers, ultra-fine admixtures, and inorganic fillers. To achieve high-value comprehensive utilization of bulk industrial solid waste.

1) Introduction to superfine ball mill classification technology:

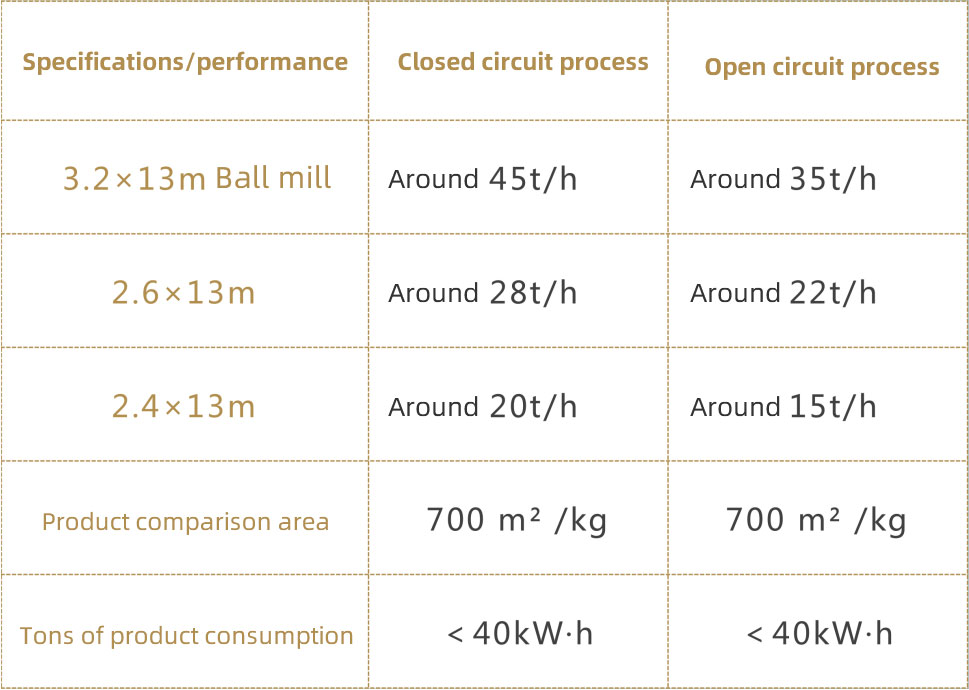

Through the redesign and arrangement of the traditional ball mill lining, grinding block, discharging device, etc., the ordinary ball mill is upgraded to an ultrafine ball mill, which greatly improves the efficiency of ultrafine grinding, and then cooperates with a special ultrafine grade machine to form a closed circuit. The system can grind steel slag, slag, fly ash, furnace bottom slag, construction waste and other waste slag to a specific surface area of 700 or more. The comprehensive energy consumption per ton of product of the ultra-fine grinding system can be less than 50kW·h.

2) Process flow of superfine steel slag powder:

In order to fully reduce energy consumption, according to the principle of more crushing and less grinding, the production process from steel slag tailings to ultra-fine steel slag powder should adopt a combined grinding method, first through ultra-fine crushing and ball milling or through table roller mills, roller mills, etc. Grinding steel slag tailings to a specific surface area of about 400㎡/kg, and then enter the ultrafine classifying and ball mill system to superfine grinding until the specific surface area reaches 700㎡/kg.

3) Performance characteristics of superfine steel slag powder:

Fine particle size: Compared with ordinary steel slag powder with a specific surface area of about 400m2/kg, the specific surface area of ultra-fine steel slag powder can reach more than 700m2/kg; the negative pressure sieve 30μm sieve residue is less than 2%; the laser particle size analyzer detects the particle size distribution: D10<2μm, D50 <8μm, D97<30μm.

High activity: According to GB/T 20491-2017 “Steel Slag Powder Used in Cement and Concrete”, compared with the 28-day activity 80 of ordinary steel slag powder, the activity can be increased by more than 20%, and the 28-day activity can reach more than 100. According to GB/T 18046-2017 “Slag Powder Used in Cement, Mortar and Concrete”, the 28-day activity of S95 is 95, and the 28-day activity can reach more than 80.

Low water requirement: The ultra-fine steel slag powder optimizes the particle gradation of the cementitious system, reduces the porosity, has a better compact filling and dispersion effect, and reduces the water requirement of the system. Under normal circumstances, the fluidity of ultra-fine steel slag powder is more than 100%, and the water demand ratio is less than 95%.

Good stability: After the fineness is increased, the free calcium oxide and free magnesium oxide will be more uniformly dispersed in the hydration system and synchronized hydration and participate in the gelation reaction, and the resulting micro-swelling effect compensates for the micro-shrinkage of the system.

Flexible usage: Ultra-fine steel slag powder can be used alone: it can replace more than 30% of S95 slag powder in cement and concrete; it can also be used after being mixed with S95 slag powder in a 2:1 ratio to completely replace slag powder in cement and concrete.

Steel slag powder, slag powder, slag powder, fly ash, etc. can also be ground into ultra-fine composite powder: replace part or all of the slag powder in the primary cement, or add 10-30% in the finished cement; The commercial mix replaces all mineral powder or replaces all mineral powder, fly ash and part of cement.

Ultra-fine steel slag powder and its ultra-fine composite powder are used as ultra-fine admixtures or mineral admixtures in PC, UHPC and high-grade, high-performance concrete, which can replace silica fume, ultra-fine silica fume, ultra-fine limestone powder, etc. It can be used for compaction, water reduction and pressure-free steaming to improve the corrosion resistance and durability of concrete.

The comprehensive performance of superfine steel slag powder or superfine composite powder used in cement concrete meets or exceeds the performance of using S95 mineral powder, and reduces the cost of cement concrete.

Good benefit: The ultrafine ball mill can be retrofitted with the old ball mill, and the existing old grinding station can be retrofitted as a whole, which significantly reduces the investment. From ordinary steel slag powder to ultra-fine steel slag powder products, the comprehensive processing cost is within 50 yuan/ton.

Compared with the market price of S95 mineral powder, the benefits of partial replacement of S95 mineral powder are significant

2. Project design plan

2.1 Production scale

According to about 350,000 tons per line, 3 production lines are needed, with a total annual production of 1 million tons. Annual production time: about 7000 hours.

2.2 Raw materials

The ratio of ordinary steel slag powder produced by table roller mill is 400-450m2/kg. Total raw materials: 1 million tons.

2.3 Products

The ultra-fine steel slag powder of 700-800m2/kg, 1 million tons/year. It can also produce superfine composite powder.

2.4 Production process technical scheme

2.4.1 Production process

Raw material quantitative feeding——superfine ball mill——super fine grade——qualified products are put into storage.

2.4.2 Main equipment system

The process equipment system of this project mainly includes:

(1) Raw material measurement system;

(2) Superfine ball mill system;

(3) Super subdivision level system;

(4) Material conveying system;

(5) Central control system.

2.5 Construction conditions

1) Land occupation: The total area of the project is not less than 10,000 m2, of which the workshop area is not less than 5,000 square meters and the height is not less than 15 meters.

2) Power consumption: The total installed capacity of this project is about 11,000kW, and the annual power consumption is about 50 million kWh.

3) Water: It is produced by the dry method, and the water is very little, which can be ignored.

4) Transportation: The existing roads of the manufacturer can be used to transport raw materials and finished products. The total annual transportation volume is 1 million tons.

3. Environmental protection

This project is fully dry production, using electricity as the energy medium, and no pollutants such as sewage, smoke, and solid waste are generated during the production process; in terms of dust control, the main production link uses negative pressure production, and the auxiliary link uses environmentally friendly dust collectors. Ensure that the national dust emission standards are met; noise reduction measures such as shock absorption, sound insulation, and noise reduction are adopted to meet the national standards.

4.The project schedule

The project construction period is 6-8 months, including 3-4 months for engineering design and equipment procurement, 1-2 months for on-site construction and installation and commissioning, and 1-2 months for trial production and normal production.

5.Personnel plan

A total of about 12 production personnel are required. Among them, there are 3 quality inspectors and 9 mill workers.

6. Investment estimation

The fixed asset investment of the project is estimated to be about 60 million yuan, of which about 40 million yuan will be invested in equipment, and about 20 million yuan will be invested in civil engineering, electric power, plant, silos and other public infrastructure and equipment installation.

7.Benefit analysis

7.1 Annual sales revenue: 200 million yuan.

After the project is put into production, the normal annual output is 1 million tons of ultra-fine steel slag powder. The product sales price is 200 yuan/ton, and the annual operating income is about 200 million yuan.

7.2 Annual operating cost: 122 million yuan.

The total annual cost mainly includes power consumption, labor, sales, management, depreciation, maintenance, etc., totaling 122 million yuan. The cost estimate composition is detailed in the table below.

7.3 Analysis of annual profits and taxes.

7.3 Analysis of annual profits and taxes.

The total investment of the project is 60 million yuan, the annual sales income is 200 million yuan, the annual operating cost is 122 million yuan, and the annual profit and tax is 78 million yuan. The investment recovery period is about 2 years (including 1 year construction period).