Brief introduction of fly ash-based inorganic filler project

1. Market Introduction

The development of fly ash-based inorganic fillers is an important direction for the future green and high-value utilization of fly ash and to further increase the utilization rate. Especially in recent years, it has become the focus of research in universities and research institutes. However, due to the fine particle size requirements of inorganic fillers, the energy consumption of ultrafine fly ash grinding is too high, there is no economy, and there is no good modification technology to enable fly ash to achieve the high value of functionalization of various inorganic fillers. In thus there has been no industrialization since. After years of research and development, we have taken the lead in breaking through the low-cost ultra-fine grinding, classifying and functional high-value-added modification of fly ash in the world, and have taken the lead in realizing industrialized operations. At the same time, we have obtained a series of patents and proprietary technologies. With the in-depth improvement and development of this series of technologies, fly ash-based inorganic fillers will have huge market potential. At present, its main market applications are as follows:

1). As a chemical filler, it mainly replaces a large number of inorganic non-metallic mineral fillers, such as calcium carbonate, kaolin, talc, quartz, feldspar, wollastonite, limestone, alumina, magnesium oxide, magnesium hydroxide, aluminum hydroxide , White carbon black, carbon black, phosphorus flame retardant, etc., used for:

- Polymer materials, such as various plastics, rubbers, plastic elastomers, polyurethane elastomers, wires and cables, synthetic leather, adhesives, etc.

- Composite materials, such as FRP, wood plastic, linoleum, etc.

- Coatings, paints, such as anti-corrosion paint, wear-resistant floor paint, wear-resistant, corrosion-resistant and high-temperature resistant coatings, etc.

- Ceramic materials, such as artificial wear-resistant and corrosion-resistant marble, granite, floor tiles, etc.

- Papermaking materials, such as various fire-resistant, corrosion-resistant, abrasion-resistant, water-resistant, tear-resistant, high-stiffened specialty paper, packaging paper, corrugated paper, cartons, etc.

According to incomplete statistics, in 2016, the domestic consumption of calcium carbonate exceeded 15 million tons (excluding desulfurization and feed grade), feldspar, quartz, kaolin, bentonite and other clay minerals exceeded 30 million tons, and carbon black and silica exceeded 800 tons. In addition, the total demand for various organic and inorganic, natural and man-made functional fillers exceeds 60 million tons. With the development trend of green, composite and functional materials, the amount of fillers will increase According to preliminary research and analysis, technical evaluation and subsequent research and development prospects, fly ash can gradually replace various conventional natural or man-made fillers at a rate of 10-20% in the next 5 years, with a total capacity of 5-10 million tons.

As a common chemical filler, calcium carbonate has a wide range of applications and a large amount of low price. The fineness is mainly 10 microns. The average price per ton is about 1,000 yuan for heavy calcium and about 1,200 yuan for light calcium.

Fly ash ultra-fine beads of the same fineness replace calcium carbonate, and the performance indicators of various products have been improved, and the cost has been significantly reduced. It has great potential to replace calcium carbonate in the field of dark products.

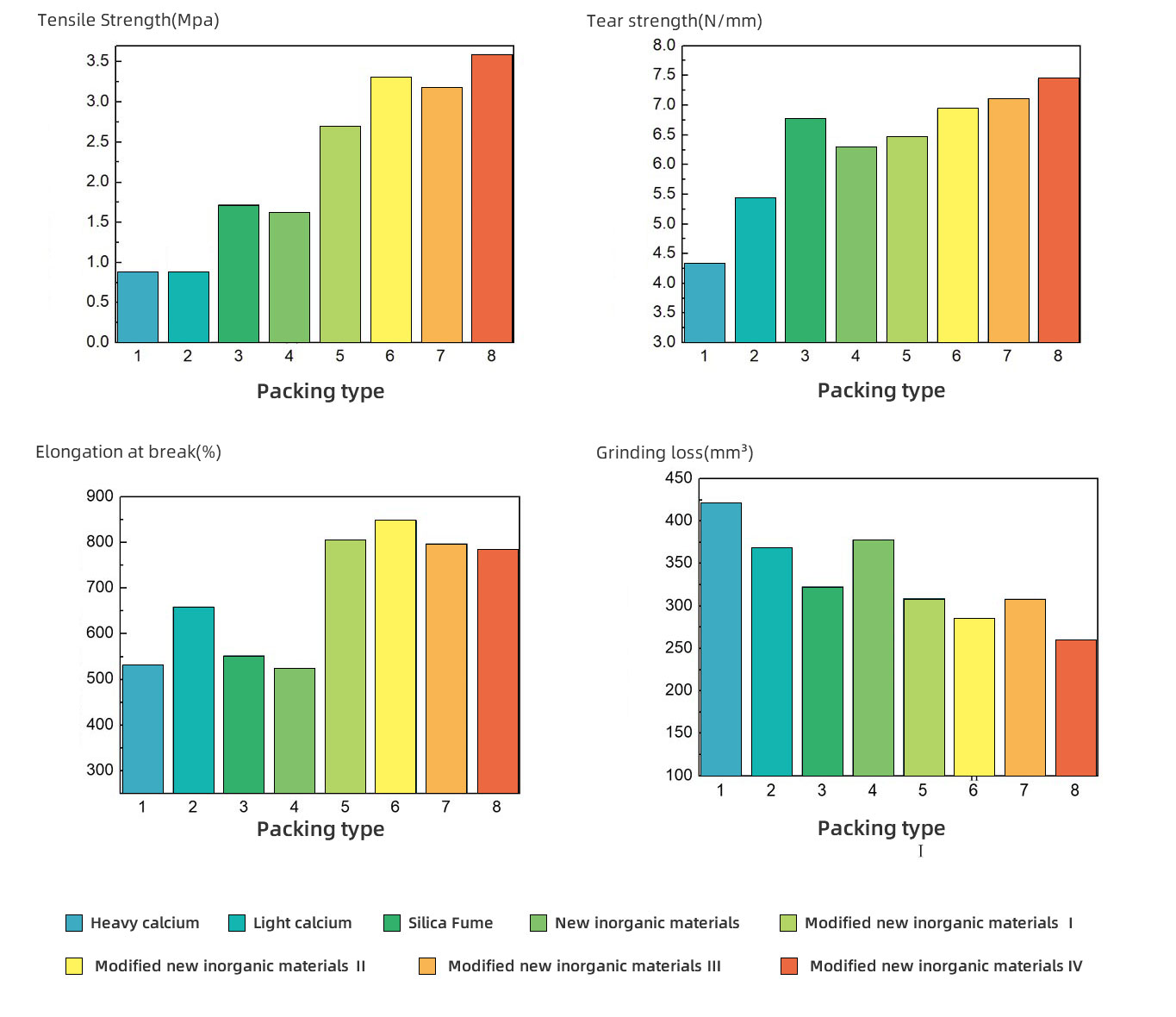

Comparing with the reinforcement performance of common inorganic fillers

Comparing with the reinforcement performance of common inorganic fillers

2) As a green high-performance superfine admixture or mineral admixture or water reducing agent, it mainly replaces cement, mineral powder, silica fume, superfine silica powder, superfine limestone powder, etc., and is used in cement, commercial mix, PC\ UHPC and other building materials to reduce costs and improve performance. Especially in large-volume, self-compacting, high-strength, high-performance, special concrete, the effect is more obvious.

Mainly because the specific surface area of this series of products can reach 700-3000m2/kg, the fineness is much finer than cement and S95 mineral powder, and the sphericity is higher than silica fume. It has good fluidity and dispersibility, and the main chemical component is activated silicon oxide, activated alumina, activated calcium oxide, etc. In the cement concrete system, on the one hand, it plays the physical role of filling, lubricating, deflocculating, dispersing, and densifying. On the other hand, the active oxides such as activated silica and activated alumina in the product interact with the hydrogen precipitated during cement hydration. Calcium oxide crystals, hydrated calcium silicate gel and other cementing materials, effective alkali, sulfate, chloride ions and other substances brought in by aggregates chemically react with substances that are unfavorable to the strength and durability of cement stone and concrete, and produce cement stone and concrete. The strength and durability of calcium aluminosilicate gel and other beneficial compounds improve the workability of fresh concrete under the action of both physical and chemical aspects, such as: good fluidity, good water retention, no bleeding, and no bleeding. Segregation, low slump loss over time, good pumpability, etc. Improve the adhesion between the paste and the aggregate interface, reduce the pores of hardened concrete, reduce the pore size, compact structure and volume stability, enhance the ability of concrete to resist various chemical erosion and inhibit alkali-aggregate reaction, and significantly improve the cement stone and concrete durability. Specifically in:

- Reduce the peak temperature of the internal temperature rise of the concrete and reduce the risk of cracks in the mass concrete.

- Improve the rheological properties, bleeding and segregation of fresh concrete, and maintain a certain degree of workability, creating conditions for reducing water consumption and forming a good durable concrete structure.

- The active silica and active alumina components in the product combine calcium hydroxide, effective alkali, sulfate, chloride ions and other substances that are unfavorable to the durability of concrete, alleviating certain chemical reactions or other effects that are unfavorable to the durability of concrete.

- Improve the density of hardened concrete structure, refine the pores, plug the pores of harmful pores, enhance the defense ability of the concrete itself against the intrusion, penetration, and diffusion of harmful substances, and protect the steel bars from corrosion and corrosion of external media.

As a high-performance concrete mineral admixture, this series of products are mainly used:

Green high-performance cement admixture and concrete superfine admixture

Use 52.5 grade cement mixed with 40%-50% to produce green high-performance 525 cement.

Use 42.5 grade cement mixed with 20%-30% to produce green high performance 42.5 cement.

Use 32.5 grade cement or mixed cement mixed with 20%-25% to produce green high-performance 32.5 cement.

Anti-chloride ion corrosion concrete mineral admixture

It is used to prepare C30-C100 seaports, wharves, roads in high-cold areas and other severely corroded concrete.

Non-pressure steam prestressed concrete mineral admixture

It is used to prepare C40-C120 high-speed rail sleeper slabs, pipe piles, meshes, poles, TRC plates, GRC plates, culvert pipes and other prestressed concrete.

Sulfate-resistant concrete mineral admixture

It is used to prepare C30-C100 subways, tunnels, sewage pipes, underground projects and other concrete with severe sulfate erosion.

Anti-abrasion concrete mineral admixture

Used to prepare C30-C100 airport runways, highways, flood gates and other highly abrasive concrete.

Radiation-proof concrete mineral admixture

Used to prepare C30-C100 nuclear power plant nuclear island containment, hospitals and other nuclear radiation concrete.

Anti-dry cracking concrete mineral admixture

It is used to prepare C30-C100 air-dried concrete with severe temperature difference between day and night.

Carbonate resistant concrete mineral admixture

Used to prepare C30-C100 high carbon dioxide concentration concrete.

Self-compacting concrete mineral admixture

Used to prepare C30-C100 vibration-free concrete.

Fair-faced concrete mineral admixture

Used to prepare C30-C100 paint-free facing concrete.

Imitating ecological concrete mineral admixture

Used to prepare landscape concrete for growing plants.

With the improvement of ecological civilization construction and environmental protection requirements, on the one hand, the prices of cement and mineral powder are increasing, while the traditional cement and commercial mixed market capacity base is huge. Therefore, replacing ordinary cement and mineral powder with fly ash-based coal and electricity solid waste ultra-fine filler has great market potential and economic benefits; on the other hand, with the rise of prefabricated building materials and green high-performance concrete, it will replace silica fume and other minerals. The admixture has huge market potential and significant benefits. At present, the market price of silica fume is more than 2,000 yuan per ton. Substituting fly ash microbeads for silica fume can significantly reduce the cost and improve performance of high-performance concrete, with significant benefits.

3) Applications in other high value-added fields. Such as:

Use fly ash microbeads instead of alumina powder to make ceramic membranes. Using its spherical microbeads as a porogens can achieve better filtration effects and greatly reduce the cost of raw materials.

Utilizing the hollow, microporous and spherical characteristics of fly ash microbeads, it can be used for heat preservation, noise reduction, light weight, adsorption material or carrier, etc.

2. Introduction to products, processes, investment and benefits

1). Superfine fly ash beads

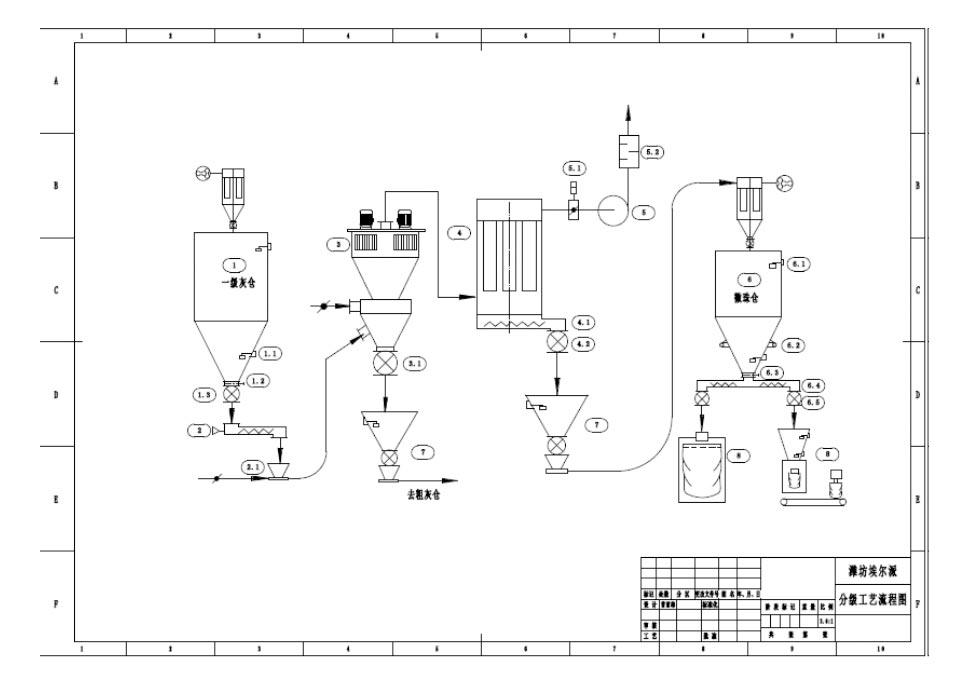

Production process: the original ash is pre-sorted to obtain first-grade ash or fine ash, and then ultra-fine beads are obtained from the first-grade ash by a special ultra-fine grade machine, and the remaining crude product can be used as high-quality second-grade ash.

Main technical and economic indicators:

Fineness: mainly 1250 mesh (D97, 10um), 600-2500 mesh adjustable

Production rate: based on original ash, 1250 mesh products can get about 10%

Calculated as the first grade ash, 1250 mesh products can get about 30%

Energy consumption per ton of product: about 50-60kWh based on 1250 mesh

Product price per ton: based on rubber and plastic fillers instead of calcium carbonate, the price is 600-800 yuan

Additives instead of silica fume meter, the price is 2000-2500 yuan

Gross profit per ton of product: 200-300 yuan for rubber and plastic fillers, 1000-2000 yuan for additives

Investment and land occupation: The total investment of 1250 mesh products per 10,000 tons is about 2 million yuan, of which about 1.5 million yuan is invested in production line equipment, covering an area of about 200 square meters

2) Compound mineral admixture (superfine admixture)

Production process: Through the transformation and upgrading of traditional ball mills to ultra-fine special ball mills, and supporting special ultra-fine classify systems, under a reasonable formula, low-cost processing and multi-solid waste synergistic excitation technology are used to make fly ash, slag, steel slag, Industrial solid wastes such as furnace bottom slag and desulfurized gypsum become composite mineral admixture products with high added value, high strength and high performance. This greatly increases the added value and consumption of solid waste processing and utilization, and reduces the cost and performance of cement and concrete.

The main technical and economic indicators:

Product fineness: specific surface area is about 650-800 ㎡/kg

Raw material formula: mainly fly ash accounts for about 40-70%, ore powder accounts for about 20-40%, and part of bottom slag, steel slag, etc. can also be added

Energy consumption per ton of product: about 40-50kWh

Price per ton: Refer to the price of S95 mineral powder when used in cement and commercial mix. It can be higher than the price of cement in UHPC or C60 or higher concrete

Gross profit per ton of product: about 80-500 yuan

Investment and land occupation:

The total investment for the new 300,000-ton production line is about 15-20 million yuan, the old line renovation (the original grinding station, etc.) needs about 8-12 million; the total investment for the new 400,000-ton production line is about 20-25 million yuan. Does not include land investment.

The area is no less than 5000 square meters, of which the workshop area is no less than 2000 square meters.