10 ways to comprehensively utilize marble tailings and waste residues

As the main building decoration material, about 70% of marble resources are converted into waste during the mining, cutting and grinding process, causing serious waste of resources and environmental pollution. The problem of comprehensive utilization is imminent.

Marble tailings are non-metallic minerals, and their main component is calcium carbonate. At present, there are mainly the following ways to comprehensively utilize marble tailings and waste residues:

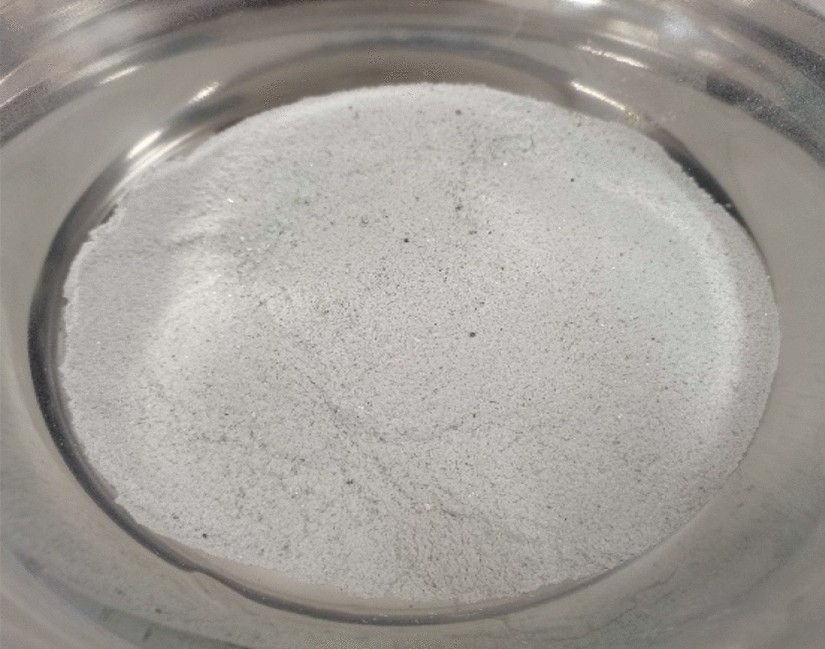

1. Used to produce calcium carbonate

The marble tailings are washed with water, dehydrated and screened, and the marble tailings with a particle size of >50mm are used as raw materials for the production of light calcium carbonate or heavy calcium carbonate.

The main component of marble waste is calcium carbonate, and light calcium carbonate can be prepared by conventional calcination-digestion-carbonization process. Lu et al. used hydrothermal treatment process in alkaline solution to reduce the concentration of colored impurity ions in the powder through the dissolution-recrystallization process of marble powder, and prepared high-whiteness calcium carbonate powder, which is expected to be applied to the large-scale utilization of marble waste.

2. Used in the production of imitation stone coatings

Imitation stone coatings are mainly composed of natural waste stone powder, binders, additives, etc., and are made into imitation stone coatings that meet different requirements according to the proportion of stone powder with different particle sizes and different colors. Marble tailings and waste slag can be ground to a certain fineness and used as fillers for imitation stone coatings.

3. Used in the production of artificial granite

Artificial granite is a synthetic stone made of marble crushed materials and stone powder as the main raw materials, and mosaics, shells, glass and other materials can also be added as embellishments. Organic resin is used as a binder, and it is vacuum stirred, high-pressure shaken to form, and then cured at room temperature.

4. Used in the production of concrete

Using waste marble as aggregate or partially replacing cement in concrete can improve the mechanical properties of concrete, mainly including wear resistance, compressive strength, flexural strength, etc. The replacement amount (relative to cement) ranges from 5% to 40%.

5. Used in the production of desulfurizers

The use of waste marble powder to prepare desulfurizers is highly efficient, and the cost of producing desulfurizers is also greatly reduced, but this method requires a high purity of waste marble powder.

6. Used in the production of machine-made sand

In recent years, the state and local governments have successively issued a number of policies to encourage the use of tailings, wastewater, etc. to produce machine-made sand. Marble tailings with a particle size of 5mm to 50mm are used as raw materials for the production of machine-made sand.

7. Used in the production of soil conditioners

The alkalinity of marble waste is used to neutralize acidic soils, and basically no damage is caused to the soil. Using marble powder and rice husk ash as soil additives can improve soil expansion rate and expansion pressure.

8. Used in the production of composite materials

A certain amount of marble waste can be mixed with ceramics or polymers to study the production of composite materials. Choudhary et al. used marble waste powder to fill glass fiber. When 20 wt% marble powder was added to the composite, the flexural strength and flexural modulus of the composite material were significantly improved. Nayak et al. used marble powder as a secondary filler in a glass polyester material system to prepare wear-resistant hybrid composite materials.

9. Used to produce aragonite whiskers

Luo Dongshan et al. used quicklime obtained by pretreatment and calcination of tailings from a marble mine in Shimian County, Sichuan as raw materials, magnesium chloride as a crystal control agent, and used carbonization method to prepare aragonite whiskers. At a temperature of 80°C, a MgCl2 concentration of 0.2 mol/L, and a quicklime dosage of 6 g/L, aragonite whiskers with a length of 40~50μm, a diameter of 2~3μm, and an aspect ratio of 13~18 can be prepared.

10. Used as filter media for wastewater treatment

There are many methods for chemical treatment of industrial wastewater. Among them, there are three types of filter media for filtration and neutralization method (suitable for acid concentration is not too high): limestone, marble and dolomite. If there is a factory nearby that needs to treat acidic wastewater, it is a good idea to select them and use them as filter media.